30

monty 3550 / 3550AIR

USA - CANADA

4.1-4

4.1-5

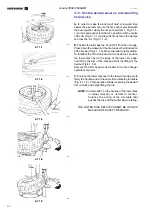

4.1-6

4.1-7

4.1-8

331.tif

332.tif

333.tif

334.tif

335.tif

RESULT IF THE BEAD IS BROKEN AT ANY OTHER

POINT ON THE RIM.

C

. Set the rim clamps to the proper position: retract clamps

to clamp the wheel from the inside and expand clamps to

clamp from the outside.

Clamping the wheels from the outside set the clamps at

diameter nearly equal to the rim diameter, before placing

the wheel on the clamps. This will avoid the risk of pinching

the tire.

WARNING

TO MINIMIZE THE RISK OF SCRATCHING ALLOY

RIMS, THESE SHOULD BE CLAMPED FROM THE

OUTSIDE

D

. Liberally lubricate both beads.

Place the wheel

WITH DROP CENTER UP

(Fig. 4.1-4)

on the turntable, and clamp in position. Hold the tire and

wheel down while clamping.

E

. Position the mount/demount head in contact with the

rim edge and lock it into place: the tool automatically

moves away from the rim edge vertically. Turn the

adjustment knob until the mount/demount head clears

from the rim flange about 1/16" (2 mm): this is necessary

to avoid rim damage (Fig. 4.1-5).

NOTE

:

The plastic insert inside the mount/demount tool must

be periodically replaced. Every machine is

equipped with several plastic inserts (inside

standard equipment box). If desired, a steel

roller also included in the standard equipment

box may replace the plastic insert. Follow the

instructions included with the replacement

parts.

NOTE

:

Once the mount/demount head is positioned properly,

matching wheels may be changed without

having to reset the head.

F.

Insert the bead-lifting tool under the bead and over the

support of the mount/demount tool. Lift the bead onto the

mounting finger. To facilitate this operation, press with left

hand on the bead in position diametrically opposite to that

of the tool. If desired, the bead-lifting tool can be removed

after lifting the bead onto the finger (Fig. 4.1-6).

G

. Rotate the turntable clockwise and at the same time

push down on the tire sidewall to move the bead into the

drop-center of the rim (Fig. 4.1-7).

H

. Repeat the process for removing the lower bead. With

left hand, lift the bead in position diametrically opposite

the tool to keep it in the drop center (Fig. 4.1-8). Move the

swing arm aside and remove the tire.