❏

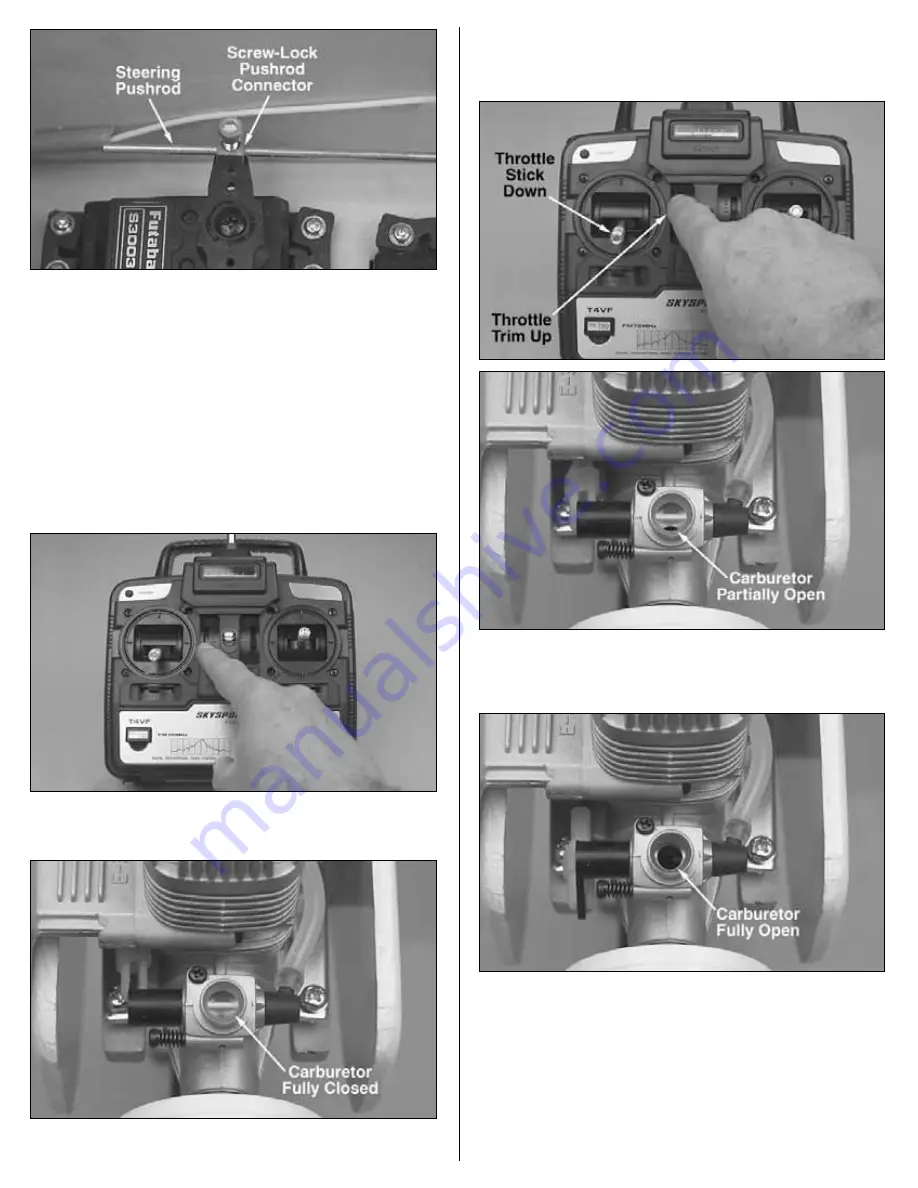

4. Center the nose wheel by adjusting the pushrod in the

screw-lock pushrod connector on the rudder servo.

Adjust the Throttle

The throttle is to be set up so that when the throttle stick is all the

way down and the throttle trim lever is all the way up, the

carburetor barrel will be

nearly closed and the engine will run at a

low RPM (“idle”). This will allow the engine to keep running when

the throttle stick is pulled all the way down (toward you) for landing.

When it

is time to shut the engine off after landing, move the trim

lever down to close the carburetor barrel the rest of the way.

❏

1. With the transmitter and receiver on, move the throttle trim

lever and the throttle stick all the way down.

❏

2. Observe the opening in the carburetor. If the carburetor is

fully closed, proceed to step 3. If the carburetor is nearly, but

not fully closed, loosen the screw on the screw-lock connector

on the throttle servo arm and move the pushrod forward until

the carburetor is closed. Securely tighten the screw.

❏

3. Move the throttle trim lever all the way up, but leave the

throttle stick all the way down.

Now the carburetor should be

partially open about 1/32" to 1/16" [1 to 2mm].

❏

4. Move the throttle stick all the way up. The carburetor

should be fully open.

❏

5. If you are not able to achieve these settings, more or less

movement may be required from the throttle pushrod. This is

done by relocating the clevis on the carburetor arm to the other

hole, or by relocating the pushrod connector on the servo arm to

another hole. From the factory, the connector on the servo arm

should be in the third hole out from the center and the clevis on

the carburetor should be in the hole closest to the screw.

6