10

VERTIC 2 Fortissimo user guide

Version 12/2018

E

E

V

V

A

A

L

L

U

U

A

A

T

T

I

I

O

O

N

N

O

O

F

F

T

T

H

H

E

E

N

N

U

U

M

M

B

B

E

E

R

R

O

O

F

F

H

H

O

O

I

I

S

S

T

T

O

O

P

P

E

E

R

R

A

A

T

T

I

I

N

N

G

G

C

C

Y

Y

C

C

L

L

E

E

S

S

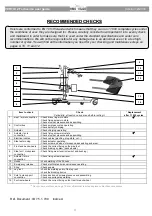

This table below, indicates if the replacement of axis and spare parts is necessary, in function of the number

of runs a day.

number of runs / a day

1

2

3

4

5

6

7

8

9

10

1

365

730

1095

1460

1825

2190

2555

2920

3285

3650

2

730

1460

2190

2920

3650

4380

5110

5840

6570

7300

3

1095

2190

3285

4380

5475

6570

7665

8760

9855

10950

4

1460

2920

4380

5840

7300

8760

10220

11680

13140

14600

5

1825

3650

5475

7300

9125

10950

12775

14600

16425

18250

6

2190

4380

6570

8760

10950

13140

15330

17520

19710

21900

7

2555

5110

7665

10220

12775

15330

17885

20440

22995

25550

8

2920

5840

8760

11680

14600

17520

20440

23360

26280

29200

9

3285

6570

9855

13140

16425

19710

22995

26280

29565

32850

10

3650

7300

10950

14600

18250

21900

25550

29200

32850

36500

11

4015

8030

12045

16060

20075

24090

28105

32120

36135

40150

12

4380

8760

13140

17520

21900

26280

30660

35040

39420

43800

13

4745

9490

14235

18980

23725

28470

33215

37960

42705

47450

14

5110

10220

15330

20440

25550

30660

35770

40880

45990

51100

15

5475

10950

16425

21900

27375

32850

38325

43800

49275

54750

16

5840

11680

17520

23360

29200

35040

40880

46720

52560

58400

17

6205

12410

18615

24820

31025

37230

43435

49640

55845

62050

18

6570

13140

19710

26280

32850

39420

45990

52560

59130

65700

19

6935

13870

20805

27740

34675

41610

48545

55480

62415

69350

20

7300

14600

21900

29200

36500

43800

51100

58400

65700

73000

21

7665

15330

22995

30660

38325

45990

53655

61320

68985

76650

22

8030

16060

24090

32120

40150

48180

56210

64240

72270

80300

23

8395

16790

25185

33580

41975

50370

58765

67160

75555

83950

24

8760

17520

26280

35040

43800

52560

61320

70080

78840

87600

25

9125

18250

27375

36500

45625

54750

63875

73000

82125

91250

26

9490

18980

28470

37960

47450

56940

66430

75920

85410

94900

27

9855

19710

29565

39420

49275

59130

68985

78840

88695

98550

28

10220

20440

30660

40880

51100

61320

71540

81760

91980

102200

29

10585

21170

31755

42340

52925

63510

74095

84680

95265

105850

30

10950

21900

32850

43800

54750

65700

76650

87600

98550

109500

Oldness of the hoist (years)

Prévoir le remplacement du

vérin, des axes et des pièces

d’usure

*

Remplacer vérin,

axes et pièces d’usure

Continuer l

’utilisation et l’entretien

périodique hebdomadaire du

releveur

Foresee axles and spare

parts replacement.

*

Replace axles and

spare parts.

Keep using the hoist.

*

See spare parts list page 12