HITBOT Z-Arm

2140

E-Mail: [email protected]

APP Software Instructions of Z-Arm

2140

Technical support mailbox:

Reply in 24 hours

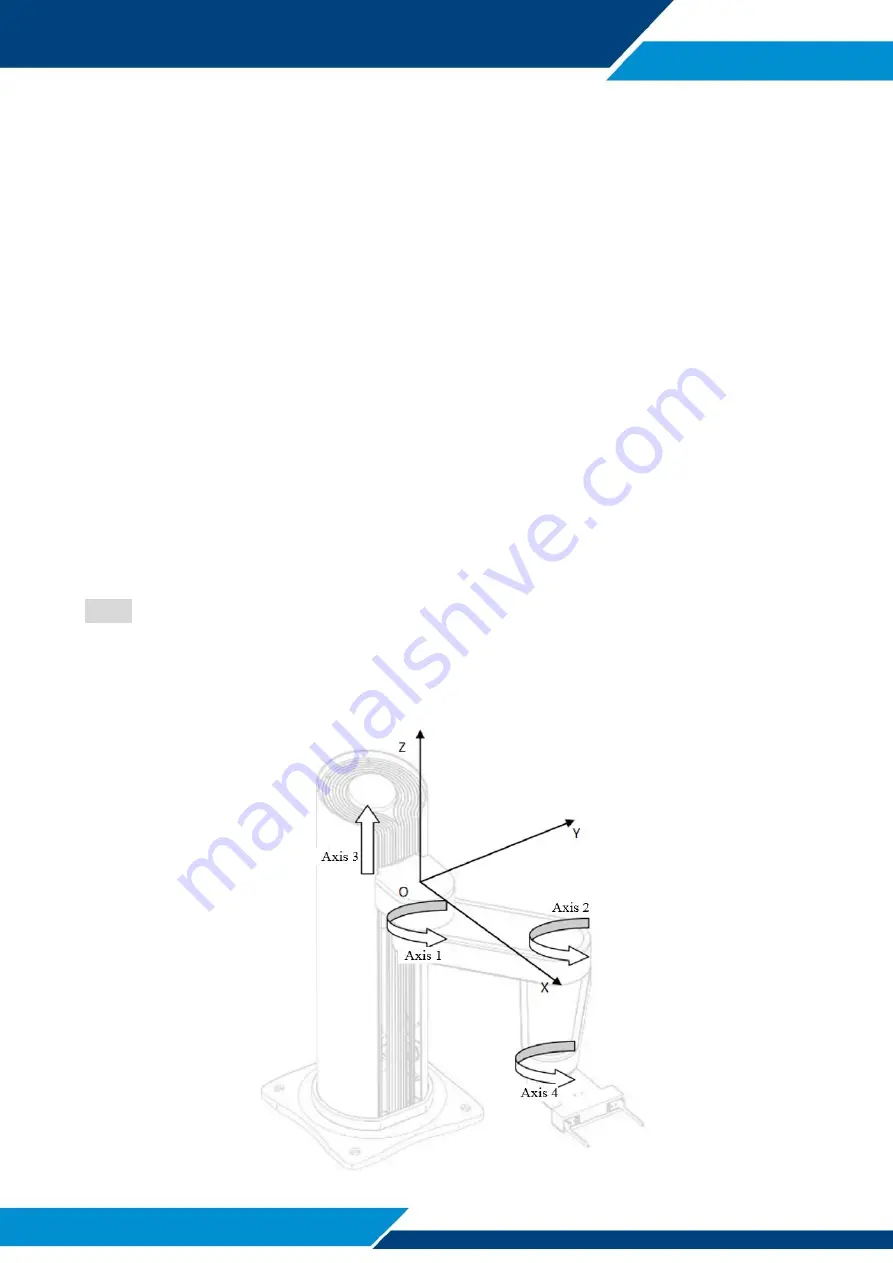

Before you start, you need to know the basic information below:

When it is controlled by the mobile terminal, the range of motion of each joint is defined as

follows:

Z axis (axis 3): [-210/-310mm, 0], the highest point is 0, and downward is negative;

Big arm (axis 1): [-90 degrees, 90 degrees], the front of the robot arm is 0°, and clockwise is

negative, counterclockwise is positive;

Small arm (axis 2): [-180 degrees, 180 degrees], the big arm along the direction away from the

machine is 0°, and clockwise is negative, counterclockwise is positive.

The end (axis 4): [-180, 180], the front of the machine is 0 °, and clockwise is negative,

counterclockwise is positive.

Note: At some special positions, the range of motion may be less than the above instructions.

For example, when the big arm is at 90° the small arm cannot reach 180° when it moves

anticlockwise, because it will collide with the machine.

Huiling-tech Robotic Co., Ltd