-23-

•

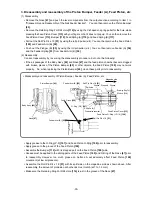

Reassembly of the control valve section

Roll pinholes

Pin groove

Pin groove

Pinholes

Valve Bushing (B)

[88]

concave portion

Valve Bushing (A)

[98]

concave portion

Match these

Valve Bushing (A)

[98]

Valve Bushing (A)

[98]

Plunger

[95]

(2) Reassembly

Conduct reassembly by reversing the disassembly procedure, but note the following:

(a) Reassembly of the control valve section

•

Always keep the control valve section clean.

•

Fully apply grease to the O-Ring (S-16)

[87]

, O-Ring (1AP-5)

[96]

and O-Ring (S-6)

[97]

of Valve

Bushing (A)

[98]

, O-Ring (I.D 1.8)

[94]

of the Plunger

[95]

, O-Ring (P7-U)

[89]

, O-Ring (P9-U)

[90]

and O-Ring (1AP-11)

[92]

of the Valve Piston

[91]

, and O-Ring (S-14)

[86]

and O-Ring (S-16)

[87]

of

Valve Bushing (B)

[88]

.

•

Match the concave portion of Valve Bushing (A)

[98]

with that of Valve Bushing (B)

[88]

as shown

below, and then insert the two Pin D2 x 8

[85]

into both. For reassembly on the Body Ass’y

[42]

,

first insert the roll pin puller (ø 3) by making sure the pin passes through the roll pinhole, and then

hammer in the two Roll Pin D3 x 28

[100]

. Orient the splitting of Roll Pin D3 x 28

[100]

as shown

below at reassembly.

NOTE: Always match the roll pin groove of Valve Bushing (A) [98] with the roll pinhole of the

Body Ass’y [42] before hammering in the roll pin. Otherwise, the periphery of Valve

Bushing (A) [98] will be damaged, thereby inhibiting disassembly and reassembly of

the control valve section.

•

After reassembly, make sure that the Plunger

[95]

moves smoothly.

Roll Pin D3 x 28

[100]

Splitting direction