--- 24 ---

(b) Reassembly

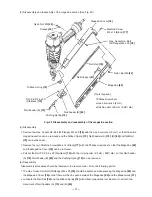

Disassembly procedures should be followed in the reverse order. Note the following points:

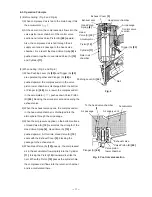

Be extremely careful to prevent the entry of foreign particles into the control valve section.

Thoroughly apply grease to the O-ring (I.D 1.8)

[69]

on Plunger (A)

[68]

, O-ring (S-4)

[64]

, O-ring (I.D 8.8)

[63]

and O-ring (I.D 11)

[66]

on Valve Piston (B)

[65]

, and the shaft of Plunger (A)

[68]

as shown in Fig. 19.

As shown in Fig. 19, install Valve Bushing (A)

[70]

so that the roll pin groove in Valve Bushing (A)

[70]

will be

aligned with the roll pin hole in the Body Ass’y

[30]

. First, insert a roll pin puller (3 mm (.118") dia.) into the roll

pin hole. Then, upon confirming that the puller passes through the hole, drive in the Roll Pin D3 x 28

[54]

.

If an attempt is made to drive the roll pin with force when the roll pin groove in Valve Bushing (A)

[70]

is

not aligned with the roll pin hole in the Body Ass’y

[30]

, it will damage the periphery of Valve Bushing (A)

[70]

and prevent disassembly or reassembly.

After assembling, check that Plunger (A)

[68]

moves smoothly.

Body Ass’y

[30]

Fig. 19

Roll pin hole

Roll pin groove

Valve Bushing (A)

[70]

Assemble

Roll Pin D3 x 28

[54]

Plunger (A)

[68]

Valve Bushing (A)

[70]

Coat the O-ring

groove's shaft with

grease.

Apply grease to the stem.

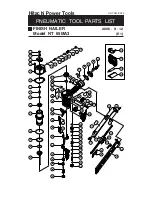

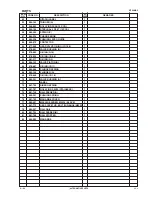

Summary of Contents for NT 65MA3

Page 37: ......