--- 19 ---

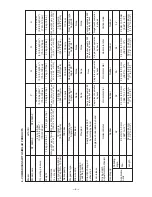

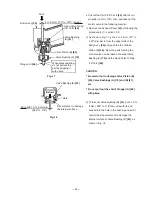

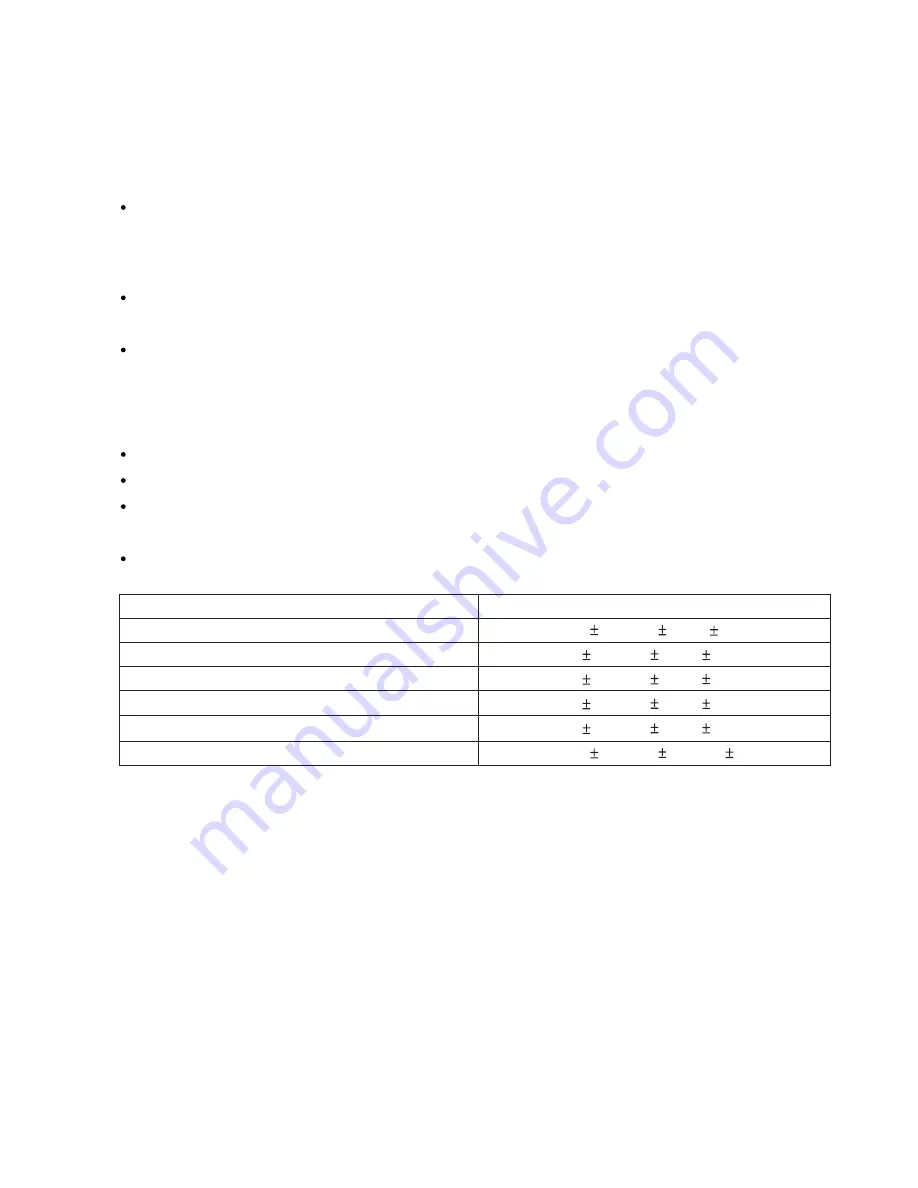

Tightening torque N

•

m (kgf

•

cm, ft-lb)

12.7 0.8 (130 8, 9.4 0.6)

8.3 0.5 ( 85 5, 6.1 0.4)

8.3 0.5 ( 85 5, 6.1 0.4)

2.0 0.5 ( 20 5, 1.5 0.4)

9.8 0.8 (100 8, 7.2 0.6)

24.5 0.5 (250 50, 18.1 0.4)

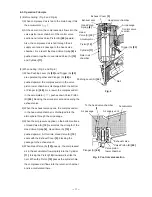

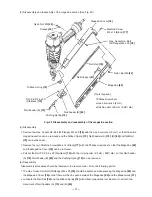

10. DISASSEMBLY AND REASSEMBLY

The items particularly necessary for disassembly and reassembly are described below. The

[Bold]

numbers in

the descriptions below correspond to the item numbers in the Parts List and exploded assembly diagram.

CAUTION:

Before disassembly or reassembly, be sure to disconnect the air hose from the nailer (with your

finger released from the trigger) to exhaust all the compressed air and remove all nails.

10-1. General Precautions in Disassembly and Reassembly

Apply grease (ATTOLUB No. 2) (Code No. 317918) to the O-rings and O-rings' sliding portions.

When installing the O-rings, be careful not to damage the O-rings and prevent dirt entry.

Oil required: Hitachi pneumatic tool lubricant

30 cc (1 oz) Oil feeder (Code No. 877153)

120 cc (4 oz) Oil feeder (Code No. 874042)

1 ltr (1 quart ) Can (Code No. 876212)

If the Gasket

[6]

is damaged, replace it and check that no air is leaking.

Be especially careful to prevent the entry of foreign particles into the control valve section.

Use the conventional grip tape for repair of the Grip Rubber

[46]

because the Grip Rubber

[46]

cannot be

mounted without the specifically designed jig.

Tightening torque for each part

Bolt and screw

Hex. Socket Hd. Bolt M6

• • • • • • • • • • • • • • • • • • • • • • • • • • • •

•

[1]

,

[32]

Hex. Socket Hd. Bolt M5

• • • • • • • • • • • • • • • • • • • • • • • • • • • • •

[4]

,

[50]

Hex. Socket Hd. Bolt (W/Flange) M5 x 20

• • • • • • • • • •

[78]

Machine Screw M5 x 15 (Black)

• • • • • • • • • • • • • • • • • • • • • • •

[77]

Valve Bushing

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

[22]

Air Plug NPT 1/4

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

[51]

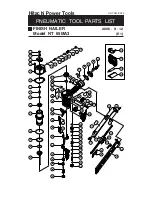

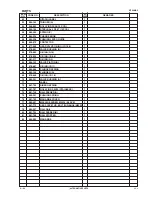

Summary of Contents for NT 65MA3

Page 37: ......