--- 10 ---

7. PRECAUTIONS IN SALES PROMOTION

In the interest of promoting the safest and most efficient use of the Model H 45MRY Demolition Hammer by all of

our customers, it is very important that at the time of sale the salesperson carefully ensures that the buyer

seriously recognizes the importance of the contents of the Handling Instructions, and fully understands the

meaning of the precautions listed on the Caution Plate attached to each tool.

7-1. Handling Instructions

Although every effort is made in each step of design, manufacture and inspection to provide protection against

safety hazards, the dangers inherent in the use of any electric tool cannot be completely eliminated. Accordingly,

general precautions and suggestions for the use of electric power tools, and specific precautions and suggestions

for the use of the Demolition Hammer are listed in the Handling Instructions to enhance the safe, efficient use of

the tool by the customer. Salespersons must be thoroughly familiar with the contents of the Handling Instructions

to be able to offer appropriate guidance to the customer during sales promotion.

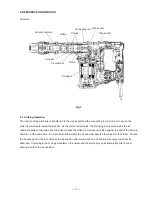

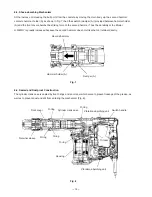

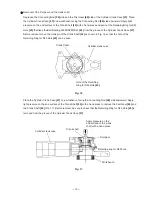

7-2. Grease Replacement

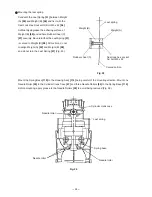

The striking portion and the speed reduction portion of the Model H 45MRY respectively use different types of

grease. Grease replacement is required if the unit is disassembled for maintenance or O-rings become damaged

and worn as described in 7-3. The striking portion uses special grease. If the striking portion (inside the cylinder

crank case) is disassembled, thoroughly remove all of the old grease from each part. On reassembly, fill 27.0 g

(0.9 oz) of new grease in the crank case (connecting rod side). Do not exceed the designated amount of grease.

Excessive grease may cause reduced striking performance.

The speed reduction portion (inside the gear cover) uses Hitachi Motor Grease No. 29 (Code No. 930035).

The proper supply volume is 20 g (0.7 oz). Never use the striking portion special grease in the speed reduction

portion. Special grease would leak into the motor portion and cause subsequent trouble.

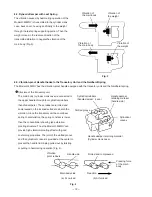

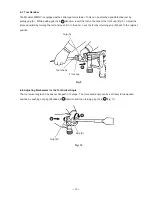

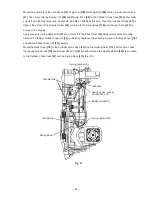

7-3. O-ring Replacement

The O-rings (mounted on the striker and the piston) are extremely important to ensure adequate sealing of the air

pressure. Although the O-rings are made of special rubber to give them a long service life, they do nonetheless

become worn, and should be replaced by new ones periodically depending on frequency of use of the tool.

With average use, it is recommended that the O-rings be replaced at least every six months to ensure maximum

effectiveness.

Summary of Contents for H45MRY

Page 36: ......