32

DP65

1.3 Comb filter operation check

Adjustment preparation

(1) Receive the color bar signal at the regular tuning

point.

(2) Set the CONTRAST control to MAX and the other

controls to center.

Adjustment procedure

(1) Check line dots condition at border of each color A, B

as follows.

A

A

A

B

3D Y/C

Dots

A None

B None

Check and line dots.

B

A

BACK TO ADJUSTMENTS

1.4 Video Settings Check

1.4.1 Color Temperature Control Check

Adjustment preparation

(1) Receive the white raster signal.

(2) Set the video controls to normal conditions.

Adjustment procedure

(1) Select the Video mode using the

GH

buttons and

press Select button.

(2) Select Color Temperature option using the

GH

buttons and press Select button.

(3) Select MEDIUM using

FE

buttons and Picture will

turn reddish slightly.

(4) Select STANDARD using

FE

buttons and Picture

will turn more reddish.

(5) Select Black & White using

FE

buttons and Picture

will turn more and more reddish.

(6) Select HIGH using

FE

buttons and Picture will turn

bluish.

Important: High Voltage adjustment should

NOT be adjusted in field. This is

adjusted at factory using precise

loads and should NOT

be

readjusted.

1.5 High Voltage Adjustment (should NOT be

readjusted in field).

Adjustment preparation

(1) Connect High Voltage meter to FBT High Voltage

output. Connect GND of High Voltage meter to CPT

GND or FBT GND.

(2) Check that High Voltage adjustment VR (RH17) is

set to mechanical center. (located behind FBT on

DEFLECTION PWB).

(3) Receive circle pattern signal.

(4) VIDEO control should be reset.

Adjustment procedure

(1) Adjust High Voltage to following spec. by turning VR

RH17 slowly. ADJ. SPEC = 31.7KV±0.2kV.

(2) After adjustment, fix VR RH17 with Silicone glue

(KE40RTV).

2. FINAL ASSEMBLY ADJUSTMENT

2.1 Cut Off Adjustment

Adjustment preparation

(1) Adjust screen VR’s on Focus Pack fully

counterclockwise.

(2) Adjust Focus VR’s on Focus Pack fully

clockwise.

(3) Set video conditions to factory preset.

(4) The vertical incident illumination on the screen

should be 20 lux or less (room should be dark).

(5) Pre-heat run time should be at least 20 min.

!

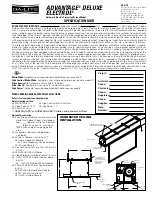

DEFLECTION PWB.

RH17

High Voltage Adjustment VR.

T

H

0

1

(F

B

T

)

Static Focus VR

R

G

B

R

G

B

Screen VR

Focus VR

Screen VR

FOCUS PACK

Summary of Contents for 51F59A

Page 89: ...CIRCUIT BLOCK DIAGRAM TABLE OF CONTENTS 88 DP65 DP65G ...

Page 90: ...DP65 DP65G CONNECTION DIAGRAM TABLE OF CONTENTS 89 ...

Page 94: ...93 DP65 CPT P W B TABLE OF CONTENTS ...

Page 96: ...TABLE OF CONTENTS FINAL WIRING DIAGRAM TABLE OF CONTENTS TABLE OF CONTENTS DP65 95 ...

Page 97: ...TABLE OF CONTENTS FINAL WIRING DIAGRAM TABLE OF CONTENTS TABLE OF CONTENTS DP65 96 ...

Page 154: ...BACK TO TABLE OF CONTENTS PRINTED CIRCUIT BOARDS DP65 CPT PWB Solder side DP65 153 ...

Page 183: ......