24

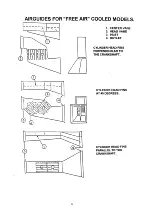

FREE AIR COOLING

Free air cooled engines, in most cases, will require some sort of special cooling shroud that

will guide enough cooling air over the cylinders and cylinder head fins to keep the engine

operating temperatures within limits.

It is generally more critical in pusher type configurations than tractor type, however; in any

case, steps must be taken to ensure proper cooling.

When constructing air-cooling shrouds (air guides), keep in mind that if the exit side of a

shroud is of larger area than the intake side, it will produce better results, as a vacuum is

created and will actually suck air through. If you were to construct an air-cooling shroud

with a larger entrance than exit, it may be possible that the engine would run hotter than with

no shroud at all. Further, usually better results are obtained when a vane is installed which

separates the air that is to pass over the cylinder from the air that is to pass over the cylinder

head fins.

Some installations may not require cooling shrouds at all, however, each installation is

different and therefore special care should be taken to find the cooling requirements of your

engine. Take extra time and be extra careful when testing to insure your shrouding is

providing adequate cooling.

The previous page gives some ideas for shrouding free air engines. Note the different angles of

the cylinder head fins. As Hirth utilizes a symmetrical 8 bolt pattern, it is possible to orient

the head fins in several different configurations on 2702, 2703, F23 and F30 models.

For further help with cooling your free air model, contact a Hirth technical representative

that can properly advise you.

Summary of Contents for F-23

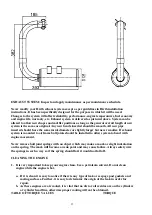

Page 17: ...17 Note 1 inch 25 4 millimeters ...

Page 23: ...23 ...