15

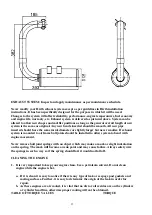

Measure the belt. It is necessary to stretch the belt 1 millimeter for every 200 millimeters of

belt length.

Recheck belt length and alignment.

Repeat procedure if necessary.

Tighten locking bolt.

Recheck with straightedge. Realign and readjust if necessary.

GEARBOX

Regardless if the gearbox is installed on the engine or not, there is NO OIL in the gearbox.

Use 85/90 W gear oil.

Fill to lower oil level plug (sight glass) on the prop flange side of the gearbox. If gearbox is

inverted the sight glass should be moved to the lower position.

Drain upon completion of initial 2-hour break-in period.

Refill oil to proper level.

See Table of Torque Values for proper torquing.

Replace oil at 12.5 hours total time.

Replace oil at 50 hours of total time.

Replace oil every 50 hours of operation or 1 year whichever comes first.

Remove gearbox and inspect elastomeric dampener or centrifugal clutch, (as equipped) every

100 hours.

RECOIL STARTER

When recoil starter is removed, apply a small amount of grease to the annular spring which

hold the clamp rollers in place.

When recoil starter is to be installed it is necessary to install it by the following procedure;

insert the three M6 Allen screws but only tighten until snug.

Make sure that the ignition is “off,” and the engine cannot fire.

Make sure that the recoil starter can still be moved in a rotating motion.

Temporarily restrict the engine crankshaft from movement.

Pull on the starter handle. You will notice that the starter has centered itself.

With tension still on the starter handle, tighten the three M6 Allen screws.

Release handle.

Remove crankshaft restricting device.

Pull through a few times and ensure a smooth rewind.

More in-depth servicing of the recoil starter is best left to a Hirth Service mechanic.

Summary of Contents for F-23

Page 17: ...17 Note 1 inch 25 4 millimeters ...

Page 23: ...23 ...