Part No. 4801-1015 Rev 6-09

Super-Saver XL Heater – 120 Volt

Page

16

of

25

b

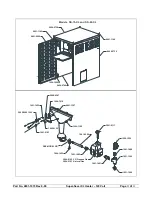

Gate

valve

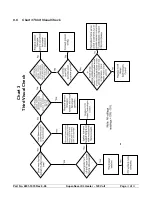

Arbitrary Piping System

a

c

d

e

f

g

Heaters

Heaters

30

m

8

m

Gas meter

8

m

tees

10. Pipe Sizing Guidelines

10.1 Calculating HVR & ELOP

1.

Using a system schematic, label each piping

section of the system starting at the meter or

regulator. A different pipe section starts

where the gas demand of the system

changes, usually at a junction.

2.

Determine the Heating Value Required

(HVR) in BTUH (BTU's per hour) for each

section of pipe.

HVR = (no. heaters supplied by pipe

section) X (heat output per heater)

3.

Determine the Equivalent Length Of Pipe (ELOP)

required for sufficient gas service.

ELOP = (length from meter to most remote heater)

+ (Minor loss equivalents of the system)

IMPORTANT: Use the ELOP value from this

equation for size determination of all pipe sections.

4.

Use the ELOP value from step 3, and the HVR of

each pipe section to determine the required pipe size

for either natural gas (NG) (Table 1) or liquid propane

(LP) (Table 2) from the table 'Maximum Capacity Of

Pipe'.

10.2 Directions for Reading Pipe Size from Tables:

EXAMPLE: Four 40,000 BTUH (12 kW) heaters will be installed on the gas pipe line in the 'Arbitrary Piping System'

diagram below. NOTE: Values given in English and Metric equivalent units.

1. Determine the HVR value for each pipe section of the system.

Pipe Section

No. Of Heaters

HVR Calculation

HVR Value

BTUH

kW

BTUH

kW

a-b

4

4 x 40,000

4 x 12

160,000

48

b-c

2

2 x 40,000

2 x 12

80,000

24

c-e

1

1 x 40,000

1 x 12

40,000

12

b-d

1

1 x 40,000

1 x 12

40,000

12

b-f

1

1 x 40,000

1 x 12

40,000

12

c-g

1

1 x 40,000

1 x 12

40,000

12

2. Determine the ELOP. Length from meter to most remote heater = length from a to e (or g) = 100ft (30m) + 25ft

(8 m) = 125ft (38 m) Minor loss equivalents from Table 1 = 1 gate valve x 2ft/valve (1 m/valve) + 3 tees x 11

ft/tee (4 m/tee) =35ft (13 m). Calculated ELOP = 125ft (38 m) + 35ft (13 m) = 160 ft (51 m) Tabulated ELOP =

200ft (60 m) Round up to the nearest table value.

3. In the appropriate table, NG (Table 2) or LP (Table 3), select the column showing the ELOP or the next longer

length, if the table does not give the exact length. Use this column to compare table values to the HVR values.

Use the Natural Gas table (Table 2) in this example. From step 2,

ELOP = 200ft (60 m) Locate the column labeled 200ft

(60 m) in Table 2.

4.

Select a pipe section and read down the ELOP column to

find the maximum gas capacity that matches the HVR for

that particular pipe section. If the exact value is not

listed, choose the next larger value in the column. In this

example, start with pipe section c-e. For pipe section c-

e, HVR = 40,000 BTUH (12 kW). From Table 2, column

200 ft, 40 (12) is not listed (NOTE: The table values are

in thousands of BTUH's). The next larger value of 72

(21) is read from the table, corresponding to 72,000

BTUH (21 kW).

5. Follow the row leftward until you reach the columns

labeled 'Internal Diameter' and 'Nominal pipe size'. Read

the pipe size for the particular pipe section. For

example, for pipe section c-e, the pipe size is ¾ inch

(0.824 in.) (19.1 mm). Repeat for each pipe section.