10

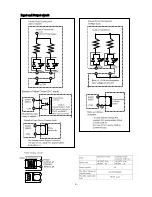

Notice of using Transformer for Multiple Axes

1.

Whenever the multiple axes driver is controlled, each of CLT-AY-61/81 Transformer should be

used individually in each sequencer or system side. Simultaneous starting operation or AND

execution of FINISH signal should be controller at each sequencer or system side.

2.

In case of open corrector Input, never connect both STARTING input terminals and in the

same way, never connect both RESET input terminals whenever the multiple axes are

controlled.

3.

In case of voltage Input, whenever both STARTING input terminal are connected, the

capacity of current should not exceed the range of possibility of sequencer or controller.

4.

In case of voltage Input, whenever both RESET input terminals are connected, the capacity of

current should not exceed the range of possibility to be driver by sequencer or controller.

Procedure of Setting and Installation

When the installation or setting this Transformer, read this manual well be make sure the safety

operation.

CAUSION: Whenever installing or setting, the Transformer must be unplugged.

1.

Confirm the matching or driver

2.

Select all built-in switches according to control system.

3.

Connect the driver and the Transformer is OFF.

4.

Wiring must be done properly referring the Construction of Input/Output Circuit or Timing

Charts.

5.

Confirm the Main SW of Transformer is OFF.

6.

After confirmation the voltage of inlet same as the rating (=AC100, 120V or 220-240V), then

connect the AC plug to the inlet.

7.

Turn the Mains SW ON.

8.

After confirmation of safety, operate the test run to observe the proper control.

9.

The actual running should be operated after observation of function is completed.