5

close the door and shut off the seconda-

ry/start-up air supply to smother the fire.

Call the fire department.

Lighting and combustion

Lighting

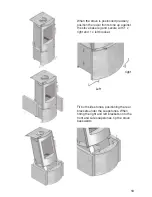

To ignite the fuel, use fire lighters, small

paraffin ignition bags or small pieces of

wood placed on the bottom grate. Place

larger pieces of wood on top of this kind-

ling material, at right angles to the firing,

doors. Completely open the start-up and

secondary air supply and leave the firing

door ajar – i.e. approx. 1 cm open. Once

the fire has taken a good hold of the fuel

and the chimney has heated up (after

about 10 min) close the firing door. We

recommend that you burn the entire first

firing with the secondary air supply fully

open to make sure that the chimney is

thoroughly heated.

Refiring

You should normally refire the stove

while there is still a good layer of embers.

Distribute the embers across the bot-

tom grate, place pieces of fuel (max

0.7 kg) on the embers in a single layer

perpendicular to the firing opening.

Close the firing door and fully open the

start-up mechanism. The wood will then

ignite very quickly – i.e. in 30 seconds

or 1 minute. When the wood is burning

with a steady flame, close the start-up

mechanism. Then adjust the secondary

airflow to the level required. For no-

minal operation (4 kW), the secondary

air supply should be 50% open. When

firing, take care not to place the pieces

of fuel too close-ly together, as this will

result in poor combustion and insuf-

ficient exploitation of the fuel. Please

note that the start-up

mechanism must not remain open during

normal operation of the stove, as this

may lead to overheating. It must only be

used until the fuel is burning with a

steady flame.

Reduced burning

The stove is well-suited to intermittent

use. If you wish to operate the stove

with reduced out-put, simply insert smal-

ler volumes of wood at each firing, and

apply a lower airflow. However, remem-

ber that the secondary combustion air

supply must never be shut off complet-

ely during firing. It is important to keep

a good bed of embers. Gentle heat is

released when the fire settles - i.e. when

the wood no longer generates flames

and has been converted to glowing

embers.

Optimal firing

To achieve optimal firing and the hig-

hest possible effect, it is important to

make sure that the air supply is used cor-

rectly. As a general rule, the secondary

air is to be used to control the fire to ig-

nite the flue gases. This produces a high

effect and keeps the glass panel com-

Handle for secondary air.

Closed position: handle to

the left.

Handle for airflow while

firing.

Closed position: handle to

the left.