2

Congratulations on your new stove. We

are sure that you will be happy with

your investment, especially if you follow

the advice and instructions we have put

together in these operating instructions.

The Scan-line 7 series has been appro-

ved according to the DIN EN 13240, NS

3058/3059, DINplus and 15a B-VG.

Approval means that consumers can be

sure, that the stove meets a range of

specifications and requirements inten-

IMPORTANT

1. Make sure there is adequate provision

to sweep the chimney.

2. Make sure there is adequate ventila-

tion to the room.

3. Please note that any extraction fans

operating in the same room as the

wood-burning stove can reduce the

chimney draft – which may have an

adverse effect on stove combustion

properties. In addition, this may cause

smoke to be emitted from the stove

when the firing door is opened.

4. It must not be possible to cover any

air vents.

The floor

It is essential to ensure that the floor

surface can actually bear the weight of

the stove and a top-mounted steel chim-

ney, if applicable. The stove must stand

on a nonflammable surface such as a

steel floor plate or a brick or tile floor.

The size of the nonflammable surface

used to cover the floor area must match

national and local regulations.

The chimney connection

The chimney opening must follow na-

tional and local regulations. However,

the area of the opening should never

be less than 175 cm

2

, which corresponds

to a diameter of 150 mm. If a damper is

fitted in the flue gas pipe, there must al-

ways be at least 20 cm

2

of free passage,

ded to ensure that the materials used

are of good quality, that the stove does

not adversely affect the environment,

and hat it is economical to use.

With your new stove you should have

received the following:

a. Operating instructions

b. A stove glove

Safety clearances

Stoves must always be installed in line

with national and, if applicable, local

regulations. It is important to abide by

local regulations regarding setting up

chimneys and connection to same. The-

refore, always consult your local chimney

sweep before installation, as you are

personally responsible for ensuring that

the applicable regulations have been met.

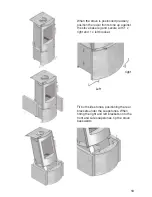

Distance regulations

A difference applies to installation next

to flammable and non-flammable walls.

If the wall is made of non-flammable

material the stove can, in principle, be

placed flush against it. However, we re-

commend leaving a gap of at least 5 cm

to facilitate cleaning behind the stove.

The minimum distances to flammable

material are stated on the boiler plate

and are listed in the table on page 6.

Warning

A stove gets hot. (In excess of

90 degrees) Take care to ensure

that children and elderly or

infirm people cannot come into

contact with it.

Combustible materials should

not be stored in the compart-

ment below the ashpan.

INSTALLATION INSTRUCTIONS