17730-241

63

AR2 Conversion from RT•RTE

AR2

™

40K • 46K

SECTION 9

AR2 Conversion from RT•RTE

This section is only for the

conversion from a Hendrickson RT•RTE rear suspension

[52" or 54"

(1,321 mm or 1,372 mm) axle spacing, with a 9½" or 10½" (241 mm or 267 mm) ride height]

to

AR2.

All other conversions to AR2 will require approval from Hendrickson Engineering .

Prior to removal of the existing RT•RTE suspension, all the following inspection and measure

-

ments need to be checked and recorded . The truck must be on a level surface prior to making

any measurements:

■

Check and record rear suspension ride height (Bottom of frame to axle centerline)

■

Check and record drive axle pinion angles

■

Mark existing suspension centerline on frame

■

Verify the total vehicle alignment is within specification

■

Verify the lateral alignment is within specification

■

Check for irregular tire wear

■

Road test (Note any unusual noise or vibration)

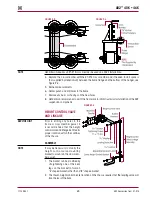

pERIpHERAL COMpONENTS

A complete inspection of the equalizing beams, torque rods, and frame rails and peripheral com-

ponents should be performed prior to suspension removal . If any of these components are found

to be worn it will be necessary to replace them . Check for any driveline or axle interference on the

vehicle chassis prior to suspension removal . Verify that the axle stops are installed by the vehicle

manufacturer and in good condition . If the vehicle is not equipped with axle stops contact the

vehicle manufacturer for the correct amount of articulation allowed for the rear suspension . After AR2

installation is complete, check for proper clearance with all suspension and chassis components .

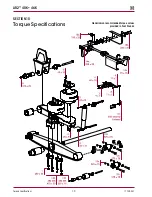

FASTENERS

Hendrickson recommends when servicing the vehicle, replace all removed fasteners with new

equivalent fasteners . Maintain correct torque values as specified . See Hendrickson’s Torque

Specifications section of this publication . If non-Hendrickson fasteners are used, follow torque

specifications listed in the vehicle manufacturer’s service manual .

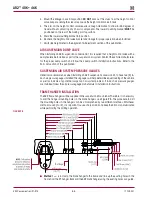

EquALIzINg BEAMS

If the equalizing beams are equipped with

bronze center bushings

it will be necessary to

replace

them with rubber center bushings.

If the equalizing beam inspection requires the replacement of the bar pin style end bushings

equipped with alignment shims it is recommended that replacement bar pin alignment shims be

installed in the neutral position prior to the equalizing beam installation . This should position the

axles square to the centerline of the vehicle prior to alignment .

All pre-existing components that are to be re-used for the AR2 installation must be replaced if

they are not in serviceable condition . An installation drawing of the AR2 suspension is normally

supplied with a AR2 suspension kit . Installers should ensure that they have the correct assembly

drawing for the vehicle to which the AR2 is to be installed, questions can be addressed by contact-

ing Hendrickson Engineering at 630-910-2800 .

CROSS MEMBER

Hendrickson requires an RT•RTE cross member (not supplied by Hendrickson) be used on all AR2

installations . To obtain the correct cross member, contact the vehicle manufacturer .