18

2: Getting Started

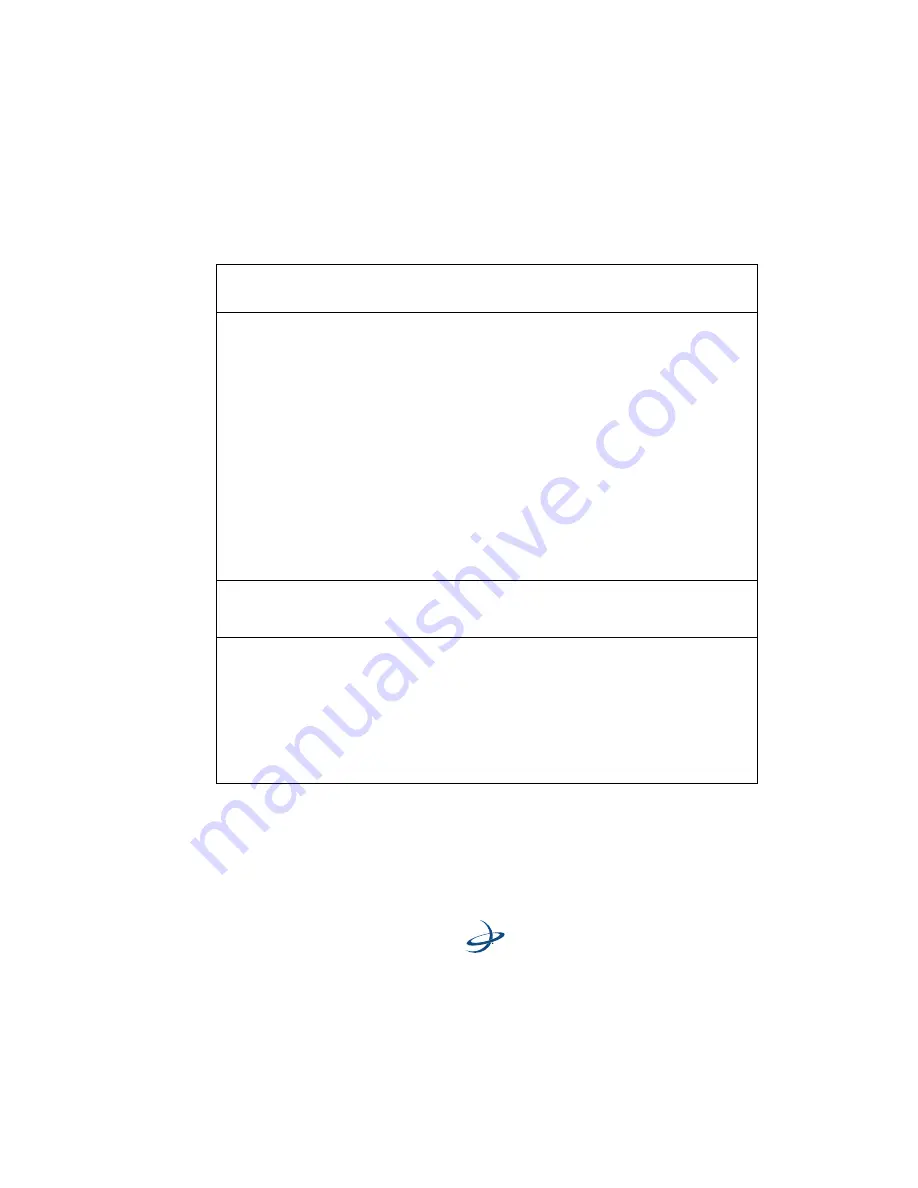

Steering Adjust

<=DN UP=>

ENTER TO STOP

<<<DN UP>>>

ENTER TO STOP

Press DOWN ARROW to

move vehicle steering to

the left.

Press ENTER to stop at

left extreme.

Press UP ARROW to

move vehicle steering

to the right.

Press ENTER to stop at

right extreme.

Adjust steering control

rate knob to achieve

desired end-to-end

steering cycle time.

Auto Engage

Auto Engage

>Off

[On, Off]

Default= Off

Select ON if you want

the Auto Engage feature

to be enabled.

Diagnostics

Ver 2.87

Gyro 0

Displays current

eDriveTC console

software version, and

internal gyro sensor

data. The number

indicates vehicle turning

rate (in degree/second),

negative to the left,

positive to the right.

Table 2-2: eDriveTC Setup Menu Options

Menu Item

Display

Sequence

Defaults

Description

Summary of Contents for eDriveTC

Page 1: ...Outback eDrive User Guide Part No 875 0171 Rev C1 ...

Page 3: ......

Page 9: ...iv ...

Page 10: ...1 Overview Product Overview What s Included Parts Listing ...

Page 13: ...4 1 Overview Parts Listing ...

Page 15: ...6 1 Overview ...

Page 16: ...2 Getting Started Overview Installing the eDriveTC Powering the Unit System Configuration ...

Page 32: ...3 eDriveTC Operation Guidance Overview Auto Disengage Auto Engage ...

Page 40: ...4 Troubleshooting Fine Tuning Performance Troubleshooting Tips Vehicle Type Setup Table ...

Page 65: ...56 Appendices ...

Page 66: ...www hemispheregps com e mail info hemispheregps com ...