76

Rev. 05/2020

77

Rev. 05/2020

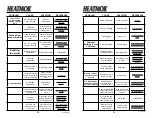

PROBLEM

CAUSE

SOLUTION

REFERENCE

Improper installation

of coil in forced air

furnace

Call your Local

Dealer

Local Dealer

Too small a coil in

forced air furnace

Call your Local

Dealer

Local Dealer

Inadequate

Baseboard

When a water-

to-water heat

exchanger is

installed a temp

drop of 20-30°F

across heat

exchanger may be

experienced

Local Dealer

Not enough

domestic hot

water

Hot water heater is

to small

Sidearm exchanger

needs to have a

pump installed

Local Dealer

Hot and cold water

can mix in domestic

system resulting in

warm water

Call your Local

Dealer

Local Dealer

HTF temperature

not consistently

between 160-180°F

Adjust New Style

High-Limit

Local Dealer

Sidearm clogged

with scale (lime),

restricting or closing

off flow

Call your Local

Dealer

Local Dealer

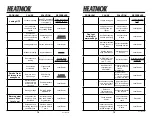

HTF in auger

tube

Condensation

formation on cooler

steel

Maintain constant

firebox temperature

“Ash Auger Tube”

HEATMOR™ STAINLESS STEEL LIMITED LIFETIME WARRANTY

HEATMOR™ warrants this outdoor furnace, to the owner, to be free of defect in material and workmanship

throughout the lifetime of the purchase. This warranty excludes the electrical components such as temperature

controls, fans, and pumps, which are covered by their individual manufacturer warranty. The bladder, firebrick,

cast iron grates, gaskets and auger are all under warranty by HEATMOR™ for a period of two (2) years from the

date of purchase. HEATMOR™ does not warranty parts damaged by freezing, overheating, pressurization, use of

unauthorized fuels, or abuse.

The HEATMOR™ is designed to be least susceptible to corrosion, however, corrosion is ONLY

covered under this warranty when

approved

water and HEATMOR’s corrosion

inhibited-propylene glycol package is maintained at a minimum of 40% mixture by volume. The

unit comes prefilled with concentrated DOWFROST™ HD corrosion inhibited propylene glycol.

DOWFROST™ HD MUST BE DILUTED WITH APPROVED WATER. Heatmor highly recommends the

use of Pure Water, such as: Reverse Osmosis, Deionized, or Distilled.

*APPROVED WATER MUST MEET THE REQUIREMENTS OF:

●

PH LEVEL OF 7.0 TO 11.5

●

CHLORIDE LEVEL OF UNDER 50 PPM

●

HARDNESS UNDER 200 PPM

●

SOFTENED AND FILTERED TO LIMIT THE AMOUNT OF SOLIDS

.

The initial five(5) years warranty coverage of the furnace weldment and ash pan is 100 percent. After five (5)

years, HEATMOR™ will credit a percent of the original purchase price of the furnace weldment and ash pan. The

percent credit from HEATMOR™ applied to the current price of a replacement unit is as follows: 70% in year 6,

60% in year 7, 40% in year 8, 20% in year 9, 15% in years 10 through 19, 10% in years 20 and beyond.

Customers will receive a percentage discount on the replacement furnace only. No cash surrender value.

The HEATMOR™ warranty only applies to the actual cost of the warranty part. The customer is responsible for

the transportation cost and labor. No other warranty is expressed or implied. HEATMOR™ is not responsible

for the cost of plumbing, replacement of antifreeze, shipping costs, or any other indirect costs associated with

the replacement of the part. Approved mixture of corrosion inhibited propylene and water must be used if you

have to drain your stove. Outdoor furnaces are not intended to be the only source of heat. Therefore, it is

recommended that a back-up system be in place to prevent damages caused by lack of heat. No unauthorized

adjustment or repairs will be covered by warranty.

HEATMOR™ is not liable for any incidents or accidents, which can be prevented by the owner or that may

occur from the operation of the outdoor furnace, or damage incurred due to heating system failure. The

owner assumes all responsibility for the care, maintenance, and safe operation of the furnace.

HEATMOR™ specifically disavows any other representation, warranty, or liability related to the condition or use of

the product.

To validate and maintain this warranty:

❏

Chloride test must be performed on water before initial fill to confirm Approved Water

❏

One Heat Transfer Fluid (HTF) sample from the unit after a minimum of 24 hours of

circulation

❏

Annual Heat Transfer Fluid (HTF) samples

❏

Heat Transfer Fluid (HTF) must be adjusted and maintained per HEATMOR™ instructions

Testing of samples will be performed to determine the quality of water being used and any

necessary additives or changes needed to your water source. Approval or instructions for your

water will be given by HEATMOR™. The product registration form must also be completed and

mailed within thirty (30) days of the purchase date. Product registration form and samples

must be mailed to: HEATMOR™, Box 787, Warroad, MN 56763.

05/01/2020

Any and all claims arising from the Heatmor Manufacturing, LLC. Limited Lifetime Warranty

shall be resolved in the State of Minnesota according to Minnesota law.