Hearth & Home Technologies • CNXT70PLUS • 4034-105 Rev C • 09/05

25

With proper installation, operation and maintenance your gas appliance will provide years of trouble-free service. If you do

experience a problem, this troubleshooting guide will assist a qualifi ed service person in the diagnosis of a problem and the

corrective action to be taken. This troubleshooting guide can only be used by a qualifi ed service technician.

12

Troubleshooting

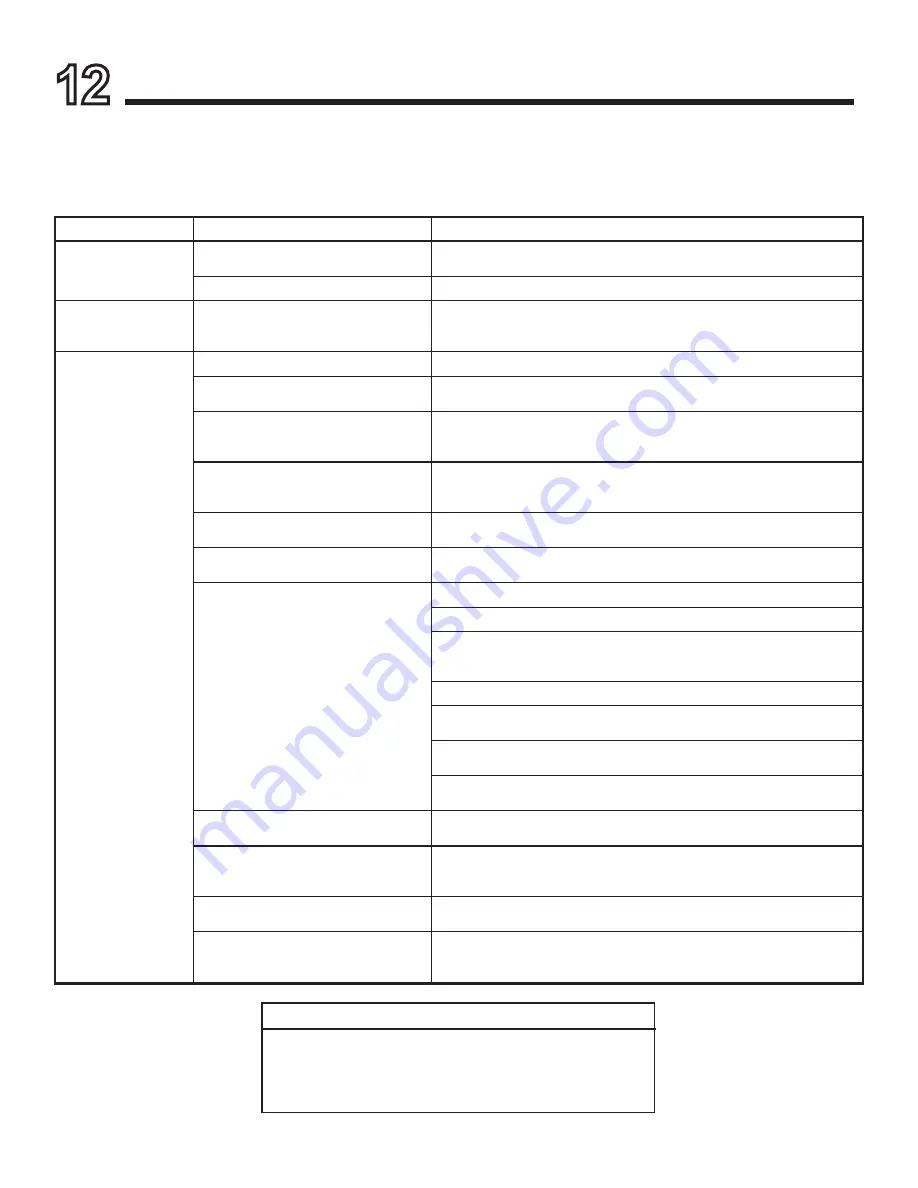

TROUBLESHOOTING GUIDE

Issues & Notes

Possible Causes

Solution

1. Blue fl ames

1. Cold start

This is normal operation and the fl ames will begin to yellow as the burners and

logs heat.

2. Glowing embers not installed

Ensure rockwool is placed per the installation instructions.

2. Odor from the

appliance

1. New appliance

The appliance may release an odor for the fi rst several hours of operation from

paint curing and manufacturing oils burning off. This is normal and will dissipate

with time.

3. Appliance does not

turn on

1. No power to appliance

Check breaker and disconnects to the appliance.

2. No power to HRV200PLUS

Check breaker to HRV200PLUS and ensure ventilator is plugged in with the door

closed.

3. No signal from the appliance to the

HRV200PLUS; i.e., 12V DC not

present at “H1” terminal

Check the wall control ON/OFF switch. Check any accessory switches

connected to REM terminals. Replace as needed.

4. No signal from the HRV200PLUS to

the appliance; i.e., 12V DC not present

at “R1” terminal

Check HRV200PLUS circuit board for jumper between 12V and R2 terminals.

Install as needed.

5. Control wiring between appliance and

HRV200PLUS incorrect

Check wiring for correct connections and continuity.

6. Appliance circuit board wired

incorrectly

Check appliance wiring per wiring diagram.

7. Inadequate draft

Check HRV200PLUS fi lters - clean as needed.

Check HRV200PLUS exhaust termination - repair, clean or replace as needed.

Check appliance exhaust venting and connections. Ensure venting is not kinked

or crushed. Ensure all connections are properly installed and secured.

Check HRV200PLUS blower motor. Ensure motor is operating on high speed.

Check HRV200PLUS blower wheels. Ensure blower wheels are clean - service

as necessary per HRV200PLUS manual.

Check HRV200PLUS heat exchanger core. Clean and service as necessary per

HRV200PLUS manual.

Check any dampers installed in the appliance exhaust or HRV200PLUS exhaust

venting. Ensure dampers are properly set.

8. Pressure switch hose cracked or

disconnected.

Check hose connecting fl ow sensor tube to pressure switch connector. Ensure

no cracks or kinks exist. Replace as needed.

9. Pressure switch bad

Install a T-connector into the pressure switch tubing and connect a digital

manometer or magnahelic gauge. If pressure reads 0.15 in. w.c. or greater and

the pressure switch electrical contacts remain open, replace pressure switch.

10. Appliance circuit board bad

Check appliance circuit board per the schematic shown in Figure 8.3. Replace

as necessary.

11. Flow sensor plugged

Attach a hose to the fl ow sensor tube and attempt to blow through the sensor.

If the sensor is plugged, apply suffi cient pressure to clear the sensor. Always

assess the cause for fl ow sensor plugging.

If sooting occurs in the appliance or if combustible

material is burned, the pressure switch ports could

close and prevent the appliance from operating.

Refer

to HRV200PLUS manual.

CAUTION