HearthStone

Quality Home Heating Products

MODEL Sterling “G” Direct-Vent

19

Gas supply

N

OTICE

A

qualified technician

must connect the heater to the gas supply and leak test the stove before it is approved for use.

Consult all local code.

W

ARNING

The stove must be installed and connected in accordance with local codes, or in the absence of local codes, with the

current edition of the National Fuel Code ANSI Z223.1

!

CAN/CGA B149 Installation Code.

High Altitude Adjustments

For high altitude installations consult the local gas distributor or the authority having jurisdiction for proper rating

methods. If the stove must be adjusted, the information sticker on page 6 (provided with the high altitude kit) must be

filled out completely and mounted to the stove per the instructions provided with the kit. This stove must be installed

in accordances with CAN/CGA 2.17 installation codes.

All the Sterlings are shipped from the manufacturer fully assembled and ready for natural gas operation with minor

adjustment. However, if the Sterling needs to be converted from natural gas to LP, conversion of the stove must be

performed by qualified service personnel using the manufacturer-supplied optional conversion kit. Follow the

conversion instructions supplied with conversion kit.

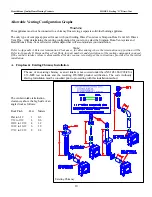

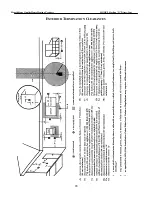

Gas Connection

The gas supply line connection is made to the Sterling’s gas control valve using a

d

" male N.P.T. fitting.

The supply line should be ½ "diameter pipe or tubing. We recommend a flexible line to avoid undue

mechanical load on the valve and to ease thread alignment.

The supply line must include a manual shut-off valve and union so that the unit can be disconnected for

servicing. The gas control valve has built in pressure taps for test gauge connections. Install a sediment trap

as close to the inlet as practical (per National Gas Code).

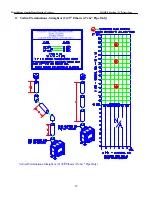

Gas Pressure Adjustment

Once connected to the gas supply, the

supply line and manifold gas pressures

must be tested. The supply line pressure

is tested to ensure it meets the minimum

gas supply pressure as listed in the

Specifications for the type of fuel in use

(NG or LP). Connect a manometer to

the supply line and adjust the incoming

pressure if necessary to meet the

required supply line pressure as listed in

the Specifications. The manifold outlet

pressure is tested by connecting the

manometer to the manifold pressure tap

on the Gas Control Valve

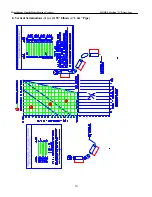

The stove and its individual shutoff valve must be disconnected from

the gas supply piping system during any pressure testing of that system

at test pressures in excess of ½" psig (3.5 kPa). The Sterling must be

isolated from the gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply

piping system at test pressures equal to or greater than ½" psig (3.5

kPa).

3" MIN.

Cap

Nipple

To Equipment

Inlet

Tee Fitting

Gas Supply

Inlet

Sediment Trap