1 3

Figure 21 - Correct Pilot Flame

Pattern

Figure 22 - Incorrect Pilot Flame

Pattern

Figure 24 - Incorrect Burner Flame

Pattern

Figure 23 - Correct Burner Flame

Pattern

!

turn heater off (see To Turn Off

Gas to Appliance, pages 10 & 11

for non-thermostat models and

page 12 for thermostat model ).

!

see Troubleshooting, pages 14

through 16.

ODS/PILOT AND BURNER

!

Use a vacuum cleaner, pres-

surized air, or a small, soft

bristled brush to clean.

CLEANING BURNER

PILOT AIR INLET HOLE

We recommend that you clean the

unit every 2,500 hours of operation or

every three months. We also

recommend that you keep the burner

tube and pilot assembly clean and free

of dust and dirt. To clean these parts

we recommend using compressed

air no greater than 30 PSl.Your local

computer store, hardware store, or

home center may carry compressed

air in a can. You can use a vacuum

cleaner in the blow position. If using

compressed air in a can, please follow

the directions on the can. If you don’t

follow directions on the can, you could

damage the pilot assembly.

1. Shut off the unit, including the

pilot. Allow the unit to cool for

at least thirty minutes.

2. Inspect burner and pilot for dust

and dirt.

3. Blow air through the ports/slots

and holes in the burner.

Also clean the pilot assembly. A

yellow tip on the pilot flame indi-

cates dust and dirt in the pilot

assembly. There is a small pilot air

inlet hole about two inches from

where the pilot flame comes out of

the pilot assembly (see Figure 25).

With the unit off , lightly blow air through

the air inlet hole. You may blow through

a drinking straw if compressed air is

not available.

Figure 25 - Pilot Inlet Air Hole

CABINET

Air Passageways

!

Use a vacuum cleaner or

pressurized air to clean.

Exterior

!

Use a soft cloth dampened with

a mild soap and water mixture.

Wipe the cabinet to remove dust.

!

INSPECTING BURNER

!

Check pilot flame pattern and

burner flame pattern often.

PILOT FLAME PATTERN

Figure 21 shows a correct pilot

flame pattern. Figure 22 shows an

incorrect pilot flame pattern. The

incorrect pilot flame is not touching

thermocouple. This will cause the

thermocouple to cool. When the

thermocouple cools, the heater will

shut down. If pilot flame pattern is

incorrect, as shown in Figure 22.

!

turn heater off (see To Turn Off

Gas to Appliance on page 11

for non-thermostat models or

page 12 for thermostat models)

!

see Troubleshooting pages 14

through 16

!

CLEANING AND

!

MAINTENANCE

BURNER FLAME PATTERN

Figure 23 shows a correct burner

flame pattern. Figure 24 shows an

incorrect burner flame pattern. If

burner flame pattern is incorrect,

as shown in Figure 24.

WARNING:

Turn off heater

and let cool before servicing

.

CAUTION:

You must keep con-

trol areas, burner, and circulating

air passageways of heater clean.

Inspect these areas of heater be-

fore each use. Have heater in-

spected yearly by a qualified ser-

vice person. Heater may need more

frequent cleaning due to excessive

l i n t f r o m carpeting, bedding

material, pet hair, etc.

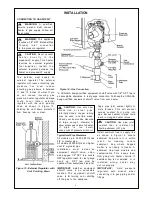

OPERATING HEATER

Continued

1. Remove lower front panel (see

Figure 7 page 7).

2. Follow steps through 5 under

Lighting Instructions on page12.

3. With control knob pressed in,

strike match. Hold match to pilot

until pilot lights.

4. Keep control knob pressed in for

30 seconds after lighting pilot. After

30 seconds, release control knob.

Follow step 8 under Lighting

Instuctions on page 12.

5. Replace lower front panel.

!

MANUAL LIGHTING

!

PROCEDURE

WARNING:

If yellow tipping

occurs, your heater could produce

increased levels of carbon monoxide.

If burner flame pattern shows yellow

tipping, follow instructions at bottom

of this page.

Notice:

Do not mistake orange

flames with yellow tipping. Dirt

or other fine particles enter the

heater and burn causing brief

patches of orange flame.

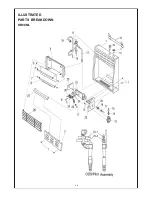

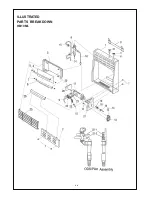

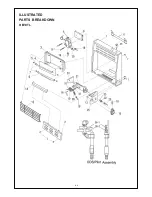

Summary of Contents for HB06ML-1

Page 18: ...1 8 ILLUSTRATED PARTS BREAKDOWN HB06ML ...

Page 20: ...2 0 ILLUSTRATED PARTS BREAKDOWN HB10ML ...

Page 22: ...2 2 ILLUSTRATED PARTS BREAKDOWN HB10TL ...

Page 24: ...2 4 ...