7

Heat & Glo • PVK-80 Power Vent Instructions • 655-900 Rev. O • 12/09

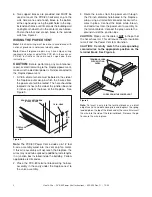

FAN

EXHAUST

PORT

EXHAUST

HOLE

Figure 13.

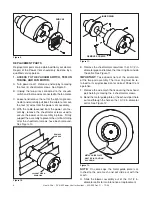

METAL GUIDE PLATE

Figure 14

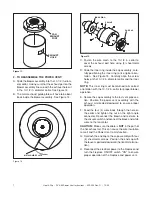

END CAP

COLLAR

INNER RING

Figure 15.

C. Fasten the wire mesh to the 10-1/2 in. collar to

cover the exhaust port hole, using (4) sheetmetal

screws.

D. Slide the inner ring inside the cap assembly, care-

fully positioning the inner ring to its original orien-

tation. See Figure 15. Carefully align the screw

holes on the 10-1/2 in. diameter collar and the inner

ring.

NOTE:

This inner ring must be returned to its correct

orientation with the 10-1/2 in. collar for proper blower

operation.

E. Secure the cap assembly to the last vent pipe sec-

tion. Position the power vent assembly with the

exhaust air directed downward to ensure proper

operation.

F. Feed the four (4) wires back through the hole on

the collar and tighten the nut on the right angle

connector. Reconnect the brown and red wire to

the vacuum switch and connect the black and white

wires to the fan motor.

CAUTION:

Make sure the cable is

NOT

in the path of

the hot exhaust air. This can cause the wire insulation

to melt and the Power Vent to malfunction.

G. Reattach the end cap to the cap assembly with four

(4) sheetmetal screws. Position the end cap with

the louvers pointed downward (horizontal termina-

tion).

H. Reconnect the electrical power to the fi replace and

turn the fi replace ON/OFF switch "ON" to ensure

proper operation of the fi replace and power vent.

2. TO REASSEMBLE THE POWER VENT:

A. Slide the blower assembly into the 10-1/2 in. diam-

eter collar, making sure that the exhaust port on the

blower assembly lines up with the exhaust hole cut

in the 10-1/2 in. diameter collar. See Figure 13.

B. The metal exhaust guide plate will have to be bent

back inside the blower assembly. See Figure 14.