13

U3

HBM 11.12.2000

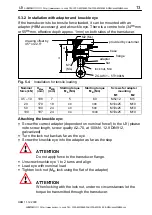

5.3.2 Installation with adapter and knuckle eye

If the transducer is to be tensile force loaded, it can be mounted with an

adapter (HBM accessory) and a knuckle eye. There is a centre hole (34

H8

mm

or 55

H8

mm, effective depth approx. 1mm) on both sides of the transducer.

H

drawing offset by

45

o

or 22.5

o

M2 (M

A

)

provided by customer

lock nut, M

B

ZGUW/1 – 5T/100kN

M1

(M

A

)

adapter

flat

B

base

flange

Fig. 5.4

Installation for tensile loading

Nominal

force (kN)

H

Max

(mm)

B

MIN

(mm)

Starting torque

M

A

(Nm)

Starting torque

M

B

(Nm)

Screws for adapter

mounting

M1

M2

0.5 – 10

108

7

5

60

M5x12

M5

20

170

18

40

300

M10x25

M10

50

180

24

40

500

M10x25

M10

100

187

24

94

1000

M10x25

M10

Attaching the knuckle eye:

•

Screw the correct adapter (dependent on nominal force!) to the U3 (please

note screw length, screw quality A2–70, at 100kN. 12.9 DIN912,

galvanized)

•

Turn the lock nut back as far as the eye

•

Screw the knuckle eye into the adapter as far as the stop

ATTENTION

Do not apply force to the transducer flange.

•

Unscrew knuckle eye 1 to 2 turns and align

•

Load eye with nominal load

•

Tighten lock nut (M

B

, lock using the flat of the adapter)

ATTENTION

When locking with the lock nut, under no circumstances let the

torque be transmitted through the transducer.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]