12

U3

HBM 11.12.2000

5.3

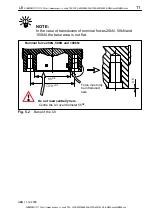

Installation for tensile loading/compressive loading

5.3.1 Installation without adapter

The transducer is screwed directly (by flange or base) on to an existing

structural element (e.g. profile, cover, plate). This type of installation enables

the transducers to measure axial forces in the tensile force and compressive

force directions. Alternating loads can also be recorded perfectly. The

transducer must be installed without axial play for this. For dynamic sustained

loading, the top and bottom threaded connectors must be prestressed by lock

nuts to above the maximum load.

drawing offset by

45

o

or 22.5

o

M

A

M

A

provided by customer

provided by customer

Flange

base

Fig. 5.3

Installation for compressive loading

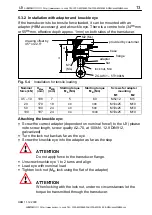

Nominal force

(kN)

Starting torque M

A

(Nm)

Thread

1)

0.5 – 10

5

4 x M5

20

40

4 x M10

50

40

8 x M10

100

94

8 x M10

2)

1)

Take note of the thread depth (see Dimensions, Page 18)

2)

12.9 DIN912 galvanized

HBM supplies knuckle eyes as mounting accessories for transducers of the

U3 type series. Knuckle eyes are suitable for use during quasi–static loading

(10Hz alternating loads). In the case of dynamic loading at a higher frequency,

you should use flexible tension bars. Knuckle eyes prevent the introduction of

torsional moments and when 2 knuckle eyes are used, stop bending moments

and transverse and angular loading being introduced in the transducers.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]