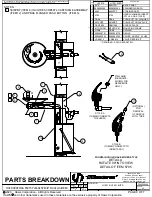

FRAME FLANGE BUTTS

BE INSTALLED SO THAT

MOUNTING FRAME MUST

IMPORTANT:

PANEL

BACK

FLANGE

FRAME

FACE

WALL

473mm

18-5/8"

76mm

3"

27"

686mm

864mm

34"

LINE

FLOOR

15"

381mm

REINSTALL VALVE & ADJUST

FLOW.

WASTE ELBOW IS INSTALLED,

REMOVE VALVE FROM PUSH

BUTTON TO INSTALL WASTE

ELBOW ONTO BOWL. AFTER

PANEL

BACK

(SUPPLIED)

SCREW

SHEET METAL

2X

INSIDE OF FRAME

(SUPPLIED)

MOUNTING CLIP

2X

GRILLE

(SUPPLIED)

FRAME

MOUNTING

SCREW

(SUPPLIED)

MACHINE

2X

15.9mm

5/8"

864mm

34"

(SUPPLIED)

GRILLE

CHILLER SUPPORT TRAY

ELECTRICAL

MOUNTING

WIDTH

FRAME

101.6mm

4"

WASTE BEND

(SUPPLIED)

ACCESS

708mm

27-7/8"

1-1/4" IPS TRAP

SUPPLY STOP &

3/8" O.D. TUBING

(NOT SUPPLIED)

FRAME

MOUNTING

13mm

1/2"

3/8" O.D.

TUBING,

INSULATION

& FITTINGS

2X

MOUNTING

(SUPPLIED)

CLIP

(SUPPLIED)

Ø

14-1/8"

359mm

(NOT SUPPLIED)

WASTE BEND

1-1/4" O.D.

44mm

1-3/4"

28-11/16"

729mm

FOUNTAIN

WASTE

SUPPLY

FOUNTAIN

MTGFR.SM

1. HOLD ROUGH-IN DIMENSIONS ±1/8" (3.2mm).

2. WHEN INSTALLING THIS UNIT, LOCAL, STATE, OR FEDERAL CODES SHOULD BE

ADHERED TO. FOR DIMENSIONS (LOCATIONS), WASTE AND SUPPLY REQUIREMENTS

OTHER THAN SHOWN, DIMENSIONS MARKED (*) MUST BE ADJUSTED ACCORDINGLY.

3. INSTALLER MUST PROVIDE TRAP FOR PROPER INSTALLATION.

4 REFER TO 5874SS OPERATION AND MAINTENANCE MANUAL FOR

PUSH BUTTON AND VALVE INSTALLATION/MAINTENANCE INSTRUCTIONS.

5 REFER TO MTGFR.SM INSTALLATION DRAWING FOR ROUGH-IN DIMENSIONS.

6 INSERT 5/16"-18 PANEL INSERTS FROM OPPOSITE SIDE AT LOCATIONS SHOWN BY

DARKENED HOLES.

7 FOUNTAIN REMOVAL: FIRST REMOVE SCREWS AND THEN SQUEEZE CLIPS ON NUT

RETAINER TO POP OUT. INSTALL IS REVERSE OF REMOVAL.

8 ALIGN HOLES IN CHILLER SUPPORT TRAY WITH HOLES IN FRAME AND FASTEN WITH

#10 SHEET METAL SCREWS.

NOTES:

4

5

5

AGAINST FINISHED WALL

FACE.

BOWL MOUNTING PATTERN DETAIL

7

6

SCREW

7

305mm

12"

359mm

14-1/8"

32-1/8"

816mm

INLINE STRAINER,

1/4" OD TUBE X

3/8" OD TUBE

INLET (SUPPLIED)

35mm

1-3/8"

HCR8

CHILLER

8

*

*

*

*

5

*

*

ROUGH-IN

ROUGH-IN

CLEARANCE

(NOT SUPPLIED)

APPROVED:

DRAWN:

PART NUMBER

SCALE:

SHEET

OF

REVISION

DRAWING TYPE:

SIZE: A

BY:

ECN NO.

PA

GE

DATE:

DATE:

ECN:

REVISED PER

CHK'D.:

Haws Corporation - All Rights Reserved. HAWS and other trademarks used in these materials are the exclusive property of Haws Corporation.

C

R

MODEL(S)

1455 KLEPPE LANE

SPARKS, NEVADA 89431

(775) 359-4712 FAX (775) 359-7424

E-MAIL: [email protected]

WEBSITE: WWW.HAWSCO.COM

THIS DOCUMENT IS TRUE AND CORRECT AT TIME OF PUBLICATION. CONTINUED PRODUCT IMPROVEMENTS

MAKE SPECIFICATIONS AND MEASUREMENTS SUBJECT TO CHANGE WITHOUT NOTICE.

RTM

07-01-97

20

0002080246.D

H1001.8/H1001.8HPS

1:15

1

1

FV

04/02/20

.

DP

7 OF

7

INSTALLATION

5527

2020

FV

SOLD SEPARATELY

REQUIRED -