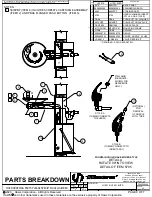

1

STRAINER ASSY

BACK PANEL

2

PUSH BUTTON, FLANGED

HEAD W/LAMINAR INSERT

4

3

SPANNER WRENCH

CHILLER

ACCESS PLATE

PUSH BUTTON W/VALVE

7

8

6

5

MOUNTING FRAME

9

1

3

4

5

6

7

8

9

H1001.8

H1001.8HPS

BP6

BP6HPS

0006983506

0006983506

6463

6463PCP

5874PBF

PBA6

5705

5705

PBA6

5874PBF

PBM1000

MTGFR.SM

HCR8

PBM1000

MTGFR.SM

HCR8

ITEM

MODEL

DESCRIPTION

10

GRILLE

0002626701

0002626719

10

2

A

DRIVER, NOZZLE .25 HEX

0002082253

11

0002082253

STYLE A

(TUBING CONNECTS

TO ELBOW)

STYLE B

(TUBING CONNECTS TO

INSERT ASSY)

(OPTIONAL)

FOR

REMOVAL

OF NOZZLE

WITH TUBE

11

(STYLE A OR STYLE B)

APPROVED

DRAWN

PART NUMBER

SCALE:

SHEET

OF

REVISION

DRAWING TYPE:

SIZE: A

BY

ECN NO.

PAGE

DATE

DATE

ECN:

REVISED PER

CHKD

Haws Corporation - All Rights Reserved

HAWS and other trademarks used in these materials are the exclusive property of Haws Corporation.

C

R

MODEL(S)

1455 KLEPPE LANE

SPARKS, NEVADA 89431

(775) 359-4712 FAX (775) 359-7424

E-MAIL: [email protected]

WEBSITE: WWW.HAWSCO.COM

THIS DOCUMENT IS TRUE AND CORRECT AT TIME OF PUBLICATION. CONTINUED PRODUCT IMPROVEMENTS

MAKE SPECIFICATIONS AND MEASUREMENTS SUBJECT TO CHANGE WITHOUT NOTICE.

WHEN ORDERING PARTS PLEASE SPECIFY MODEL NUMBER.

RTM

10-12-05

20

0002080246

H1001.8/H1001.8HPS

1:10

1

1

FV

04/02/20

.

DP

6 OF 7

PARTS BREAKDOWN

5527

2020

FV

PARTS BREAKDOWN

NOTES:

1 5874PBF (ITEM 6) INCLUDES VRK5874 CARTRIDGE ASSEMBLY

(ITEM 12) AND PBA6 FLANGED PUSH BUTTON (ITEM 5).

1

1

5

1

VALVE REPAIR KIT

VRK5874

12

VRK5874

FOUNTAIN COULD HAVE EITHER STYLE

DETAIL A

ROTATE 90°INTO VIEW

DETAIL OF ITEM 5705

5705LAMIN

(OBSOLETE -

SHOWN FOR

REFERENCE

ONLY.)

**

** REQUIRED - SOLD SEPARATELY