03/20

Model H1001.8/H1001.8HPS

Page 5 of 7

INSTALLATION PROCEDURE…

STEP 11:

Install grille and tighten outer side screws. Verify there is chilled water out of bubbler.

MAINTENANCE

STEP 1:

Periodically clean the strainer located in the valve body. Refer to 5874 Series Valve

Manual for more information.

STEP 2:

The condenser fins on chiller should be periodically cleaned with brush, air hose or

vacuum cleaner. Care should be taken not to bend or deform the condenser fins.

STEP 3:

The chiller temperature control is factory set for 50° F water under normal conditions.

For colder water, adjust control clockwise. For warmer water, turn counterclockwise.

Remove front chiller panel for access to temperature control. After adjustment allow

unit to cycle off before checking outlet water temperature.

TROUBLESHOOTING

PROBLEM

REPAIR CHECKLIST

1. Insufficient bubbler flow.

1a. Check that inlet screwdriver stop valve is in

wide-open position.

b. Verify minimum 30 psi flowing supply pressure.

c. Clean strainer. See 5874 Series Valve Manual.

d. Adjust valve to increase flow. Use front adjust

screw or see 5874 Series Valve Manual.

e.

Clean screens (inside nozzle body). Unscrew

nozzle insert and very gently activate water

supply to pop out qty. 3 screens (be careful not

to lose screens). Remove any debris clogging

the screen openings and place back into nozzle

body. Reassemble nozzle insert.

2. Water too warm or cold.

a. Adjust chiller temperature control, clockwise for

colder water.

© 2020 Haws

®

Corporation

– All Rights Reserved

HAWS

®

and other trademarks used

in these materials are the exclusive property of Haws Corporation.

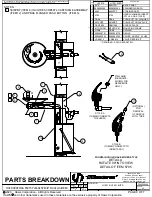

FIGURE 1