No.:GC-JS-21 Version: 01/00

Effective date

:

2020-03-30

31

9. Maintenance

In order to make this equipment work safely and reliably within the life span, periodic inspection, cleaning and

maintenance should be done.

9.1 Safety matters that should be paid attention to during equipment maintenance

:

⚫

Equipment maintenance should be carried out under sufficient light environment, and the light intensity should

not be less than 100lx;

⚫

Equipment maintenance should be carried out with the power cord disconnected and the equipment fully

cooled;

⚫

Consumables and accessories that need to be replaced should be provided by the manufacturer, otherwise it

may cause unpredictable problems;

⚫

The maintenance of the equipment should not be completed by the user, but must be performed by the

manufacturer or the personnel designated by the manufacturer.

⚫

The consumables or accessories that may be replaced by the user are:

1. Air filter; 2. Door sealing ring; 3. Safety valve 4. Power cord, 5. Other internal accessories

9.2 Maintenance plan

9.2.1 Cleaning plan

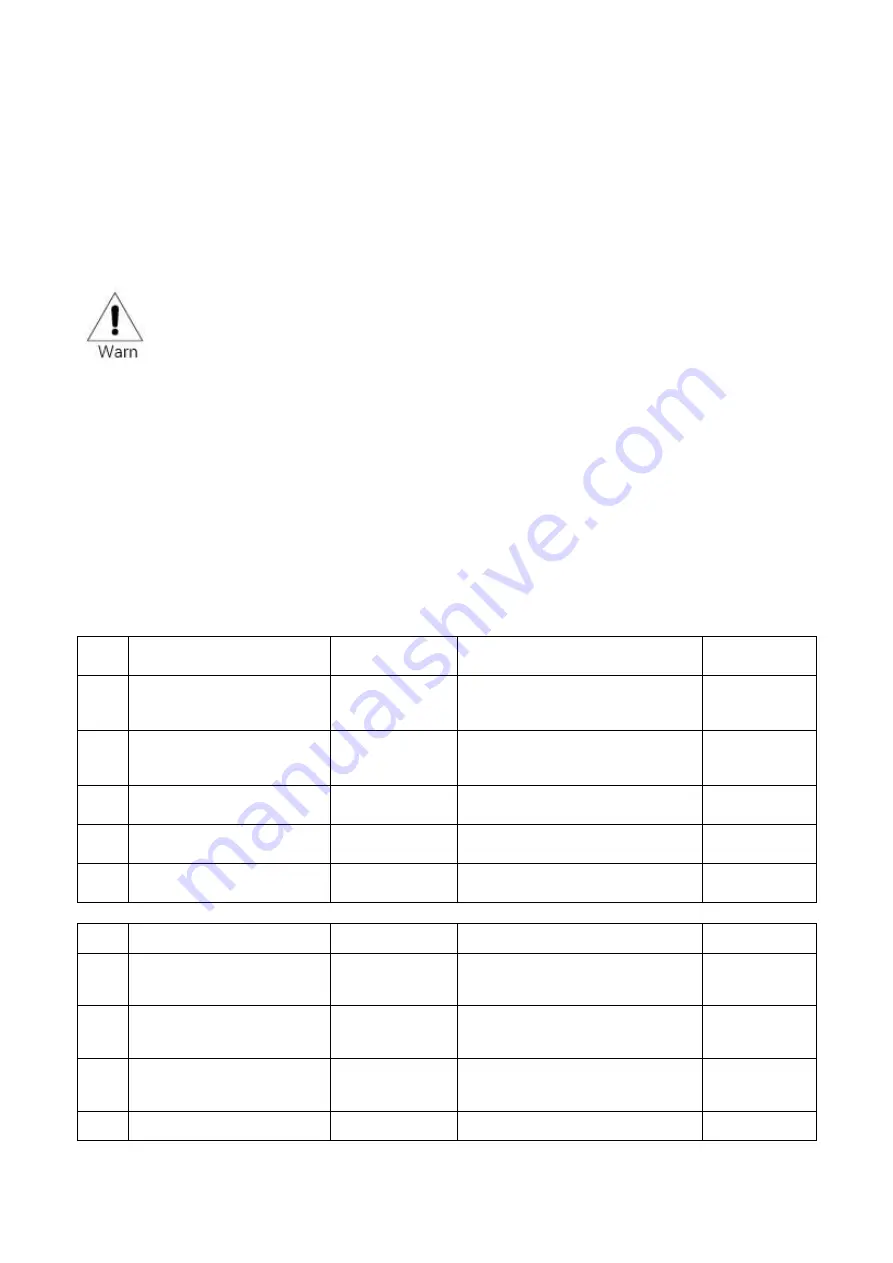

No.

Cleaning items

Cycle

Requirement

Remark

1

Sterilization

cleaning

chamber once a week

Keep clean without sewage

Refer to 9.3.1

2

Clean water tank

Once a month

No dirt on the surface of the water

tank

Refer to 9.3.2

3

Drain filter

Once a month

Filter is transparent

Refer to 9.3.3

4

Door seal

once a week

No dirt on the surface

Refer to 9.3.4

5

Water tank filter

Once a month

Filter is transparent

Refer to 9.3.5

9.2.2 Checking plan

序号

Checking items

Cycle

Requirement

Remark

1

Inspection of safety valve in

sterilization room

Every half year

Can be opened, and not opened

during the sterilization phase

Refer to 9.3.6

2

Storage tank liquid level

sensor

Every half year

There will be a reminder when

there is no water

Refer to 9.3.7

3

Water quality detection

function

Every half year

There will be a reminder when the

water quality exceeds the standard

Refer to 9.3.8

4

power cable

Every half year

No damage to external insulation

Refer to 9.3.9