Pressure Transfer Filling Procedure (Low Pressure Source) –

Once you have deter-

mined the proper full weight for a container, connect a transfer hose to the LIQUID fitting

from a low pressure source of liquid.

1. Open the supply valve. Then, on the XL-65/65HP, open the LIQUID and VENT valves to

begin the fill.

2. During the fill, monitor the container pressure and maintain a pressure of 10-15 psig

(0.7-1 bar/69-103 kPa) by throttling the VENT valve. Not for CO

2

service

3. When full weight is reached, close both the LIQUID and the VENT valves.

4. Close the liquid supply valve and open the dump valve on fill line assembly.

5. Disconnect the fill line from the container and removed the container from the scale.

Pump Transfer Filling Method

When a pump is used for filing liquid containers, the fill may be accomplished through

either the VENT valve of the LIQUID valve. Filling though the VENT valve recondenses gas

in the area over the liquid cylinder and reduces product loss during the fill. This method

will also result in the liquid near the saturation temperature of the supply vessel. Filling

through the LIQUID valve may provide colder liquid and longer holding time before the

liquid warms to the point where venting begins, but will require more frequent venting and

greater product loss.

Pump Transfer Filling Procedure -

This method applies only to containers in gas

service that are equipped with a 230 psig (16-bar/1586 kPa) or 350 psig (24-bar/2412 kPa)

relief valve. Liquid is admitted through the VENT valve and recondenses gas in the head

space during the fill. The fill line is connected from the liquid supply to the VENT valve on

the cylinder. Both the fill line and the container should be pre-cooled prior to beginning the

fill process. Proper full weight is determined by the previously explained method.

1. Open the supply valve. Then, on the container being filled, open only the VENT valve to

begin the fill. Start the pump at this time.

2. Observe the container pressure closely. If the pressure approaches the relief valve

setting (or the pump pressure rating) stop the fill process at the supply, and open the

fill line dump valve to vent excess pressure. As soon as the pressure has dropped to a

level that will allow you to resume the fill, close the dump valve and restart the pump (or

reopen the supply valve.)

3. When full weight is reached, close the VENT valve. Stop pump (when applicable),

close liquid supply valve and open the dump valve on fill line assembly to vent trapped

liquid.

4. Disconnect the fill line from the container and remove the container from the scale.

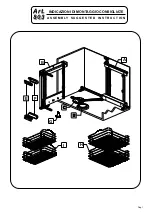

Fill Hose Kits

Taylor-Wharton fill hose kits for the XL-65/65HP are designed to transfer specific liquefied

gases to, or from, the containers. These accessories are comprised of a Fill Tee Assem-

bly and a Fill Hose. Cryogenic transfer hoses are constructed of stainless steel for the

transfer of cryogenic liquids, and are available in four of six-ft. (1.2 or 1.8 m) lengths with

a 3/8 in. NPT fitting on one end and a CGA service-specific female fittings on the other. A

Fill Tee Assembly consists of a cross fitting with a CGA end fitting, relief valve and manual

dump valve.

CAUTION:

With carbon dioxide,

pressure in the

container being filled

must be above 70 psig

(4.8 bar/482 kPa)

before the fill begins

and at all times during

the fill to prevent the

product from freezing

into dry ice.

Pump Transfer Liquid

Fill Through Vent Valve

Pressure Transfer

Filling From a Low

Pressure Source