NOTE:

The yellow band will

move approximately ¼

in. (6/4 mm) to each 10

turns on the rod.

NOTE:

Remember this

procedure is performed

with gauge in an upright

(vertical) position.

NOTE:

Make sure that the

Gauge Assembly is not

bent or out of line before

reinserting the gauge

into the container.

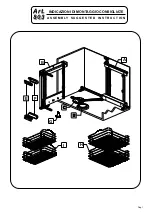

Contents Gauge Installation

Before installing a new or repaired gauge, inspect the gasket seals. If any damage is

apparent, replace the gasket. (See following page for illustration.)

1. When inserting the gauge assembly, lower the float rod through the gauge opening

until about 8 in. (203 mm) of the float rod remains above the container.

2. Grasp the clear cover portion of the gauge assembly with two fingers so that the

assembly hangs free and “plumb.”

3. Lower the assembly about 4 in. (102 mm) slowly and try to keep the rod in the center

of the threaded entrance hole as you do. If you are careful during this portion of inser-

tion, you will drop the float rod straight through the guide ring inside the cylinder.

4. To confirm that the rod is correctly positioned in the cylinder, stop where you can still

grasp the top of the rod (see illustration) and then try to swing the lower end from side

to side.

5. When the rod is engaged in the guide ring, the rod will be restricted to lower end

movement of about ½ in. (12.7 mm); if you can feel greater movement, withdraw the

rod to the point where its top is 8 in. (203 mm) above the gauge opening and try again.

Calibration

for XL-65 and

XL65HP