Debris Blower

R

R

Belt Tension Adjustment

•

Check the condition of drive belts be-

fore each use or after every 25 hours

of operation.

Note:

Use only industrial V-belts. Do not use

automotive belts.

Do not over-tighten belts. Excessive

tension can cause premature bearing and

belt failure.

Use a straightedge to check alignment

across the faces of pulleys after adjusting

belt tension to ensure that the belts will

run true.

Cable Adjustment

•

Check the condition of the diverter

cable before each use or after every

25 hours of operation.

SAFETY WARNING!

•

Never operate Debris Blower with

out ALL GUARDS in place.

SAFETY WARNING!

•

Before servicing or inspecting the

Debris Blower, make sure the power

source is shut off and all moving

parts have stopped.

•

Disconnect the PTO shaft from the

tractor.

•

Always wear safety glasses and

protective gloves when servicing

the Debris Blower.

Break-in Service

After the first hour of use:

1.

Check belts. Re-tension if needed.

2.

Tighten set screws on bearings.

3.

Check nuts, bolts and fasteners to see

that they are secure.

Lubrication

1.

Lubricate grease fittings on unit after

every 15 hours

of use.

2.

There are

8 grease fittings

on the

unit:

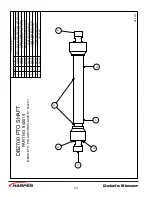

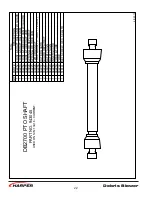

2 on the PTO Shaft

2 on the Input Shaft

2 on the Impeller Shaft

1 on each Caster Wheel (2)

Adjustments

Service & Maintenance

10

Summary of Contents for Debris DB2700

Page 1: ...Debris Blower R R R Debris Blower R 2 2012 Operator s Manual DB2700 DB3600 5 2013...

Page 2: ...Debris Blower R R...

Page 14: ...Debris Blower R R...

Page 15: ...Debris Blower R R R Debris Blower R 2 2012 Operator s Manual DB2700 DB3600 Parts Section...

Page 16: ...Debris Blower R R...

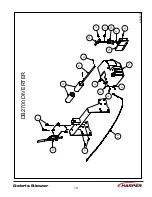

Page 21: ...Debris Blower R R 12 9 11 8 2 3 15 7 5 14 13 4 6 6 4 7 1 16 DB2700 DIVERTER 4 16 2012 10 19...

Page 35: ...Debris Blower R R NOTES...