Oakwood Woodburning Stove

Dry Seasoned Wood Only!

Harman® • Oakwood Owner's Manual_R34 • 2004 -___ • 09/15

30

3-90-08327

8

Service & Maintenance

Seasonal cleaning

At least once per year, the stove, venting connectors and

chimney should be thoroughly cleaned. If the areas are

found to have an excessive build up of ash or creosote, it

is recommended to increase the frequency of the cleaning.

This will extend the life of the appliance and its components.

A vacuum specifically designed for ash is preferred, however

a standard shop-style vacuum with a HEPA filter may also

work just fine.

During cleaning, caution must be taken not to damage the

white / gray colored ceramic combustion package in the rear

of the firebox. When using a brush in the chimney or venting

connector, the by-pass damper should be placed in the open

position to help prevent ash, creosote or other debris from

falling down onto and around the combustion package. This

also protects the top of the combustion package from tool

or brush damage and diverts most of the removed materials

into the firebox for easy clean-up and removal. Once the

venting system has been cleaned, remove the first section

of connector pipe from the appliance flue collar. Carefully

vacuum the ash and debris from around the sides and top

of the combustion package.

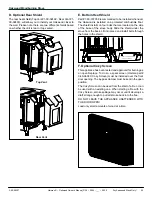

The shoe brick must be removed to allow vacuum access for

cleaning the front portion of the combustion package.

Always use caution when refueling or when vacuuming the

firebox and combustion package. Some users have damaged

their combustion package with vacuum cleaner tools, and

fire pokers.

Solid fuel burning space heaters must be cleaned regularly, as soot,

ash and creosote may accumulate.

CAUTION

!

ALWAYS WEAR FIRE-RESISTANT GLOVES TO

OPERATE THE STOVE. THE AIR CONTROL IS HOT

WHILE IN OPERATION.

When properly maintained, your wood stove will give

you many years of trouble-free service.

Contact your

dealer

to answer questions regarding proper operation,

trouble-shooting and service for your appliance. Visit www.

harmanstoves.com to find a dealer. We recommend annual

service by a qualified service technician.

A.

Creosote - Formation and Need For Removal;

When wood is burned slowly, it produces tar and other

organic vapors which combine with expelled moisture

to form creosote. The creosote vapors condense in the

relatively cool chimney flue of a slow burning fire. As a

result, creosote residue accumulates on the flue lining.

When ignited, this creosote makes an extremely hot fire.

The chimney and chimney connector should be inspected

at least once every two months during the heating season

to determine if a creosote buildup has occurred. If creosote

has accumulated, it should be removed to reduce the risk

of a chimney fire.

If you experience a chimney fire;

Close the air control

and bypass damper and notify the fire department. Do NOT

apply water to the fire, in the firebox or in the chimney. Do not

operate the appliance until the chimney and connector have

been inspected and approved by a chimney professional.

Do not burn any fuel other than wood, such as charcoal,

which can cause increased carbon monoxide production or

overfiring. Never use highly volatile substances in your stove,

such as gasoline, which could cause an explosion.

When solid fuels are burned completely, they produce

water and carbon dioxide. However, in long slow burns, a

substantial amount of carbon monoxide may be produced.

If allowed to build up, carbon monoxide (which is odorless)

can prove fatally poisonous. Proper ventilation and draft will

prevent this from happening. If you smell smoke, turn up

the air control lever setting, and thoroughly ventilate your

dwelling. During future burns, be careful not to overload

the stove with fuel, so you will not be tempted to constantly

operate at a low air control setting.

Other causes of poor ventilation or draft are icing, exhaust

fans, a blocked outside air inlet, and room air starvation. If

your stove is sluggish and you get occasional odor, check

these possibilities and increase the air flow in your home.

IMPORTANT NOTE

The only suitable method for removing creosote from

the venting system is a chimney brush. Creosote

sweeping logs, powders and other products have the

potential to damage the Firedome combustion system,

and are not recommended for use in Harman wood

stoves. Use of chemical creosote removal products

will void the warranty of the Firedome combustion

system.