18

40 Rewind ™ Radial Winch

Installation and Maintenance Manual

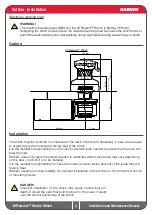

Winch assembly

Make sure that the holes and drainage channels in the base of the winch are not obstructed

Assemble the winch in the reverse order of the sequence in the section on disassembly.

To tighten bolts, use the torque indicated in the disassembly procedure.

To assemble the pawls:

correctly position the spring in its housing as

shown at left. Hold the spring closed and slide

the pawl into its housing. Once in position,

check that the pawls can be easily opened and

closed with a fi nger.

NOTICE!

Before closing the winch, make sure the holes and

drainage channels in the base of the winch are not obstructed.

NOTICE!

Before screw the central screw, check the correct

position of the o-ring in the assy socket and apply Harken

®

grease.

NOTICE!

Insert the disconnect rod in the winch, with the

groove in the lower part of the rod.

In case of doubt concerning the assembly procedure contact Harken

®

Tech Service: [email protected]

OIL

THIS SIDE

DOWN