10

ENGLISH

05/15/2022

Lokhead Winch Installation

Mounting Surface

Winch must be installed on a flat surface, reinforced if necessary,

to withstand a load equal of 22 kN.

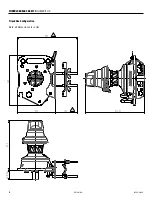

Winch Entry Angle of Lifting Rope

Winch entry angle must be 8° with a tolerance of ±2° to avoid

rope overrides.

Mount winch so drive gear is positioned where rope enters

winch drum.

Note: on winch skirt identifies location of drive gear.

Mounting Template - Plate Adapter

Drilling template of the holes provided

for fastening with M12 screws.

All dimensions are in mm.

Ø13

49

102

49

78

11

11

WINCH LOKHEAD 500 KIT

INLH500KIT.US

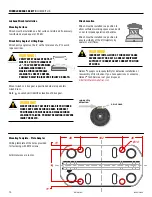

WARNING!

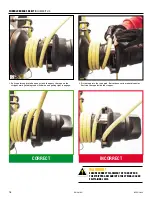

MOUNT WINCH SO THAT DRIVE GEAR IS POSITIONED

WHERE ROPE ENTERS WINCH DRUM. INCORRECT

POSITIONING OF DRIVE GEAR CAN WEAKEN WINCH

LEADING TO FAILURE, POSSIBLY RESULTING IN SEVERE

INJURY OR DEATH.

WARNING!

INCORRECT INSTALLATION OF WINCH MAY CAUSE

SEVERE INJURY OR DEATH. CONSULT EQUIPMENT

SUPPLIER IF IN DOUBT ABOUT CORRECT POSITION

OF WINCH.

8°

WARNING!

VERIFY ENTRY ANGLE OF ROPE. IT

MUST BE 8° WITH TOLERANCE OF

±2°, TO AVOID ROPE OVERRIDES

AND DAMAGING WINCH OR

MAKING WINCH INOPERABLE,

LEADING TO LOSS OF CONTROL,

POSSIBLY RESULTING IN SEVERE INJURY OR DEATH.

Winch Location

Winch must be installed in a position to

allow sufficient working space around unit,

so not to impede operation of handles.

Winch must be installed in a position to

ensure visibility of the lift trajectory by

operator at all times.

Harken

®

accepts no responsibility for defective installation or

reassembly of its winches. If you have questions or concerns,

Harken

®

Tech Service is at your disposal:

DRIVE GEAR

rope entry

direction