18

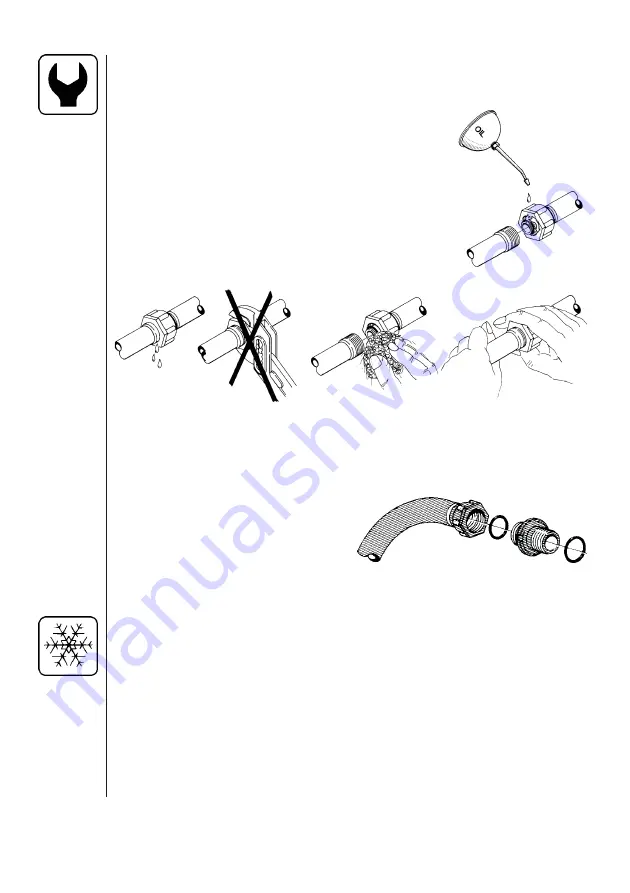

Nozzle tubes and fittings

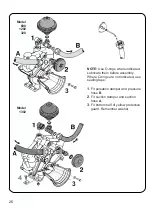

Poor seals are usually caused by;

. missing O-rings or gaskets

. damaged or incorrectly seated O-rings

. dry or deformed O-rings or gaskets

. foreign bodies

Therefore, in case of leaks: DO NOT over-

tighten. Disassemble, check condition and

position of O-ring or gasket, clean lubricate and

reassemble.

For radial connections only hand tighten them.

The O-ring to be lubricated ALL THE WAY ROUND before fitting on to

the nozzle tube.

For axial connections, a little

mechanical leverage may be

used.

Off-season storage

When the spraying season is over you should devote some extra time

to the sprayer before it is put away for the winter.

Hoses

Check that none of the hoses are caught or have sharp bends.

A leaky hose can give an annoying delay in the middle of the spraying

job. Therefore check all the hoses and change if there is any doubt

about the durability.

Summary of Contents for NL Series

Page 1: ...NL Instruction book 674202 GB 10 1995 www hardi international com ...

Page 15: ...13 1 X 40 2 A X 12 B X 40 3 X 20 16 17 17 6 10 19 ...

Page 16: ...14 4 X 40 5 X 40 15 15 ...

Page 19: ...17 Model 1302 Model 320 ...

Page 35: ...33 22 Organise hoses it may be necessary to shorten some of them Secure with straps ...

Page 36: ...34 A6 600 foot ...

Page 37: ...35 320 A8 ...

Page 38: ...36 A10 1202 foot ...

Page 39: ...37 1303 foot A12 ...

Page 40: ...38 B5 Unit M 70 70 HT ...

Page 41: ...39 Distributor B6 ...

Page 42: ...40 B300 Damper HJ73 ...

Page 43: ...41 SB 6 8 10 m D3 ...

Page 44: ...42 D5 SB 12 m ...

Page 45: ...43 Boom tube 3 8 cap D901 ...

Page 46: ...44 E3 NK 300 400 ...

Page 47: ...45 NL NK 300 400 E102 ...

Page 48: ...46 E103 NL NK 600 800 ...

Page 50: ...48 Notes ...

Page 52: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...