22

For face connections, a little me-

chanical leverage may be used.

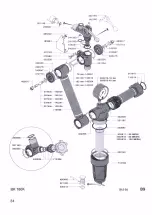

Changing of ball seat in operating unit

If problems with on/off valve occurs (dripping nozzles when on/off

valve is closed), the ball and ball seat should be checked.

Remove the 2 bolts fixing the

on/off-pressure valve unit to

the bracket, unscrew the

union nut A and pull the on/

off-pressure valve away from

the distribution valves.

Check the ball for sharp

edges and scratches and

check the ball seat for

cracks and wear - replace if necesary.

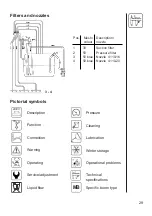

Nozzle tubes and fittings

Poor seals are usually caused by;

• missing O-rings or gaskets

• damaged or incorrectly seated O-rings

• dry or deformed O-rings or gaskets

• foreign bodies

Therefore, in case of leaks: DO NOT overtighten.

Disassemble, check condition and position of O-

ring or gasket, clean lubricate and reassemble.

For radial connections only hand tighten them.

Lubricate ALL THE WAY ROUND before fitting.

A

Summary of Contents for LX-HB Series

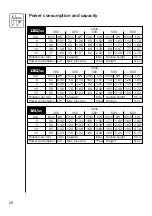

Page 14: ...1 X 40 1 X 40 2 A X 12 B X 40 3 X 20 14 20 6 10 11 22 ...

Page 15: ...15 4 X 40 5 X 40 6 X 40 7 X 40 MB MB MB MB 19 9 18 18 ...

Page 16: ...16 8 X 40 9 A X 40 B X 40 10 A X 40 B X 40 A A A A B B B B B HB HB 19 9 19 HB A A A B B ...

Page 17: ...17 11 X 40 12 A X 40 B X 40 HB HB 19 18 B A A ...

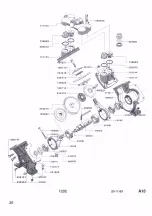

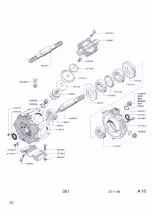

Page 21: ...21 Model 1302 Model 361 ...

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ...32 Notes 48 ...