15

ALPHA

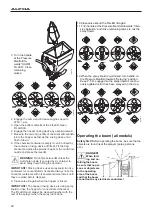

Self-cleaning filter

Operating Diagram

1.

From pump

2.

Double filter screen

3.

Guide cone

4.

To operating unit

5.

Replaceable restrictor

6.

Return to tank

7.

Nut

Choice of restrictor

It is important to have a large

flow through the filter. This is

achieved by choosing the

restrictor size in relation to

the liquid consumption of the

spray boom.

4 restrictors are supplied. Use

the green one

(largest orifice first).

The hose

N

is demounted at

the self-cleaning filter, the

restrictor is put in the hose

and the hose is mounted

again.

If the required working pressure cannot be obtained, the

restrictor is too large. Choose a smaller restrictor.

Start with a black one, then a white and finally a red one.

When cleaning the filter remove hose

N

and the hose at

the safety valve, and check there are no residues.

Standard filter size is 80 mesh. Sizes of 50 and 100

mesh are available and can be changed by opening the

filter top and replace the strainer. Check the O-rings be-

fore reassembling the filter and replace if damaged.

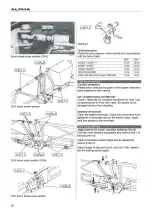

Use of MANIFOLD valve system

The following pictograms and colours are used for the

visualizing the function of the MANIFOLD valves:

Green disc = Pressure valve

Black disc = Suction valve

Blue disc = Return valve

To operate the spraying functions:

• Turn the handle on a green pressure valve towards

the function desired

• Turn the handle on a black suction valve towards the

desired function

• Turn the handle on the blue return valve towards the

desired direction of return flow

• Close all remaining valves by setting the handle(s)

on “

O

”

IMPORTANT!

The valves and functions may vary from

machine to machine depending on optional equipment

fitted. Only the functions to be used must be open - Al-

ways close remaining valves.

Black disc = Suction valve

From main tank

(suction filter)

From Rinsing

Tank

Green disc = Pressure valve

To Self-Cleaning

Filter/operating

unit

To Fast Filling

Device

To HARDI

FILLER

To Tank Flushing

Nozzle

To main tank

From Filling Device

Agitation

(spraying position)

Pumpsuction line

(to facilitate emp-

tying the tank

completely)

Blue disc = Return valve

N

T140-0014

T059-0001

T020-0002

Summary of Contents for ALPHA 2000

Page 5: ......

Page 6: ......

Page 7: ......

Page 9: ......

Page 16: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 51: ......

Page 52: ...52 ALPHA Notes...