ALPHA PLUS HARDI NOVA

M

M A

A II N

N T

T E

E N

N A

A N

N C

C E

E

CHAPTER

5

5- 26

TTh

hiiss cch

haap

ptte

err d

de

eaallss w

wiitth

h tth

he

e aaccttiio

on

nss tto

o b

be

e ttaakke

en

n ffo

orr tth

he

e p

pu

urrp

po

osse

e o

off g

gaarraag

giin

ng

g tth

he

e ssp

prraayye

err iin

n tth

he

e w

wiin

ntte

err p

pe

err-

iio

od

d.. TTh

he

eyy m

mu

usstt b

be

e ffo

ollllo

ow

we

ed

d ssccrru

up

pu

ullo

ou

ussllyy aass tth

he

e g

gu

uaarraan

ntte

ee

e d

do

oe

ess n

no

ott cco

ovve

err d

daam

maag

ge

e ccaau

usse

ed

d b

byy ffrre

ee

ezziin

ng

g

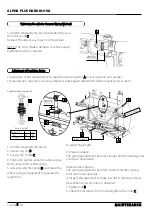

- Protect the electrical components (alternator,branch box, connectors, regulating valve) from splashes of

water.

- Clean the sprayer completely - inside and outside. Make sure that all valves, hoses and auxiliary equipment

have been cleaned with detergent and flushed with clean water afterwards, so no chemical residue is left in

the sprayer

- Renew possible damaged seals and repair possible leaks.

- Empty the sprayer completely and let the pump work for a few minutes. Operate all valvess and handles

to drain as much water off the spraying circuit as possible. Let the pump run until air is coming out of all

nozzles. Remember to drain the rinsing tank also.

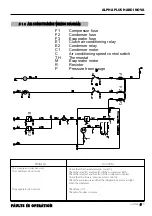

- Pour 8

80

0 to1

10

00

0 litres of water with antifreeze into the main tank. See the antifreeze instructions to obtain

sufficient protection from freezing.

- Spray for a few moments at the nozzles to protect the nozzles.

- Engage the pump and operate all valves and functions on the Manifold, operating , filler etc. allowing the

anti-freeze mixture to be distribued around the entire circuit. Open the operating unit main on/off valve and

distribution valves so the anti-freeze is sprayed through the nozzles as well.

The anti-freeze will also prevent O-rings, seals, diaphragms etc. from drying out.

- Lubricate all lubricating points according to the lubricating scheme - regardless of intervals stated.

- When the sprayer is dry, remove rust from possible scratches or damages in the paint and touch up the

paint.

- Remove the glycerine-filled pressure gauges and store them frost free in vertical position.

- Apply a thin layer of anti-corrosion oil on all metal parts. Avoid oil on rubber parts, hoses and tyres.

- All electric plugs and sockets are to be stored in a dry place. Remove the Hardi Nova control box and dis-

play from the cab and store them dry and clean (in-house).

- Apply grease on all hydraulic ram piston rods which are not fully retracted in the barrel to protect against

corrosion.

- Chock up the wheels, to prevent moisture damage and deformation of the tyres.

- Fill up completely the fuel tank to prevent condensed water into the tank.

- Clean the engine air filter

- Cut the battery cut-off and disconnect the battery.

- Place the mobile unit under cover

5

5-2

2-1

13

3 O

OF

FF

F-S

SE

EA

AS

SO

ON

N S

ST

TO

OR

RA

AG

GE

E

Summary of Contents for ALPHA PLUS 3500

Page 11: ...ALPHA PLUS TWIN FORCE 1 1 6 F F O O R R E E W W O O R R D D ...

Page 12: ...ALPHA PLUS TWIN FORCE 1 1 7 F F O O R R E E W W O O R R D D ...

Page 13: ...ALPHA PLUS TWIN FORCE 1 1 8 F F O O R R E E W W O O R R D D ...

Page 47: ...ALPHA PLUS HARDI NOVA P P R R E E P P A A R R A A T T I I O O N N CHAPTER 3 3 8 ...

Page 85: ...ALPHA PLUS HARDI NOVA M M A A I I N N T T E E N N A A N N C C E E CHAPTER 5 5 28 ...