9

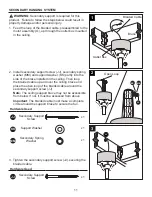

STANDARD OR ANGLE MOUNTING INSTRUCTIONS

1. Remove the downrod pin (B) and downrod clip (C) from

the downrod (A). Then partially loosen the set screws

(R) in the yoke at the top of the motor assembly (G).

2. Insert the downrod (A) through the canopy (E) and yoke

cover (O). Feed the wires and braided cable from the

motor assembly (G) through the downrod (A).

3. Slide the downrod (A) into the yoke of the motor

assembly (G), align the holes, then re-install the

downrod clip (C) and downrod pin (B). Secure with set

screws (R) and slide the yoke cover (O) down until it

rests on top of the motor assembly (G).

A

R

B

C

2

E

A

O

G

3

A

C

R

B

G

1

Yoke

Braided Cable