6

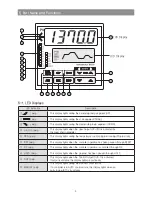

● NP200 Series Programmable Temperature Controller

Versatility is a key advantage of NP200 Programmable Temperature

Controller. The following features are incorporated into NP200 to

maximize user benefits. NP200 programs 30 patterns with 300

segments (each pattern can have maximum 99 segments). The

high performance CPU allows great accuracy (+/-0.1%) and

sampling time (100ms). Also, NP200 has multiple inputs (19 types),

multiple outputs (3 types), auto-tuning (2 types), time signal (5),

heat & cooling output, level PID calculation and control, and

emergency output functions. Large back-light display clearly

indicates unit monitored, program running, elapsed time,

temperature, and operation mode.

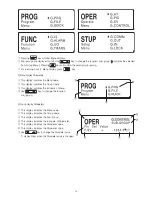

User Output

The User can set a parameter that activates the desired control output up to 10

(From U1 through U10).

User Output includes:

① Alarm (ALARM 1~4) ② Time signal (TS1~TS5) ③ Inner signal (IS1~IS5)

④ Pattern end (PTEND) ⑤ Program run (RUN) ⑥ Fixed control mode (FIX)

⑦ Reset mode (RST) ⑧ Hold (HOLD) ⑨ Wait (WAIT)

⑩ Output during the manual control (MAN) ⑪ Output during the ascending segment

⑫ Output during the descending segment ⑬ Output during the soak segment

(Be sure that U10 is assigned to Cooling Operation Output,

if a controller is the Heating/Cooling model)

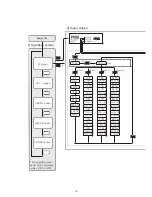

Heating/Cooling PID Control

In program control

Heating/Cooling control outputs the PID operational result in two types of signal, that is, for

heating and for cooling. You can choose either PID control or ON/OFF control for the output

of heating side and cooling side. If you set the proportional value(P) of heating side as 〞

0〟 the ON/OFF control is selected for the heating side, while the fixing of the band(Pc) of

cooling side 〞0〟 chooses the ON/OFF control for cooling side. . Moreover, you can choose

one method among heating side output, cooling side output, relay output, voltage pulse

output and current output and apply the controling function with it.

Universal Input/Output

his controller has two types of auto-tuning as STD(standard type) and LOW

(Low PV type is the value 10% lower than the set value)

2 Type of Auto Tuning Mode

(Standard/Low PV)

This controller has two types of auto-tuning as STD(standard type) and LOW

(Low PV type is the value 10% lower than the set value)

Level PID Operation

The input range is divided into four levels and differnt PID group is applied to each level.

If you choose Level function, the PID group is automatically selected by Level irrespective of PID

number or Set Value Number(SVNO). You can apply different PID data to different range to get

an optimum PID value in wide temperatare range.

● Key Features & Benefits

Summary of Contents for NP200

Page 2: ......