Hansa C65RX O&M Manual

–

OM-029 First Release 4/05/2021

© Hansa Chippers 2021

30

until the pulley separates from the bush. Slide bush off the shaft, followed by the pulley.

2.

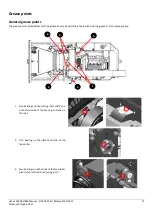

Remove two grub screws in the bearing.

3.

Remove M16 nuts and bolts bolting the bearing to the housing.

4.

Remove and replace bearing.

5.

When replacing the pulley ensure the rotor pulley is lined up to the engine pulley with a straight edge. Ensure the grub

screws are tightened evenly so the pulley is tightened evenly.

6.

The gap between the end of the sensor and the sensing plate should be approximately 4 mm. Adjust the sensor

accordingly. If it is set further away, then the sensor may not work properly and therefore the AFC will not work.

Replacing rotor bearing on inlet chute side of rotor:

It is recommended to have this bearing replaced by a specialist Hansa dealer.

Bolt torque

When servicing the machine, ensure any bolts you remove are done back up and torqued to the values listed in the torque table

below:

Torque setting

Bolt size

Bolt shaft

diameter

lb ft

Nm

M8

8 mm

16

22

M10

10 mm

32

44

M12

12 mm

57

77

M16

16 mm

140

190

M20

20 mm

274

372