P.O. Box 393

Wadsworth, OH 44282, U.S.A.

Tel: +1 330 336 4550

Fax: +1 330 336 9159

www.hstool.com

OPERATING

RECOMMENDATIONS

for MODEL MFT

Flange Facer

READ THOROUGHLY AND UNDERSTAND THIS PUBLICATION BEFORE

ATTEMPTING TO OPERATE THE EQUIPMENT.

DANGER! The application of this product requires an exposed rotating tool holder and cutting blade. It can

produce HOT, SHARP metal fragments requiring that eye, ear, and hand protection and other protective

clothing be worn at all times. Do not wear loose fitting clothing that may become entangled with the rotating

objects.

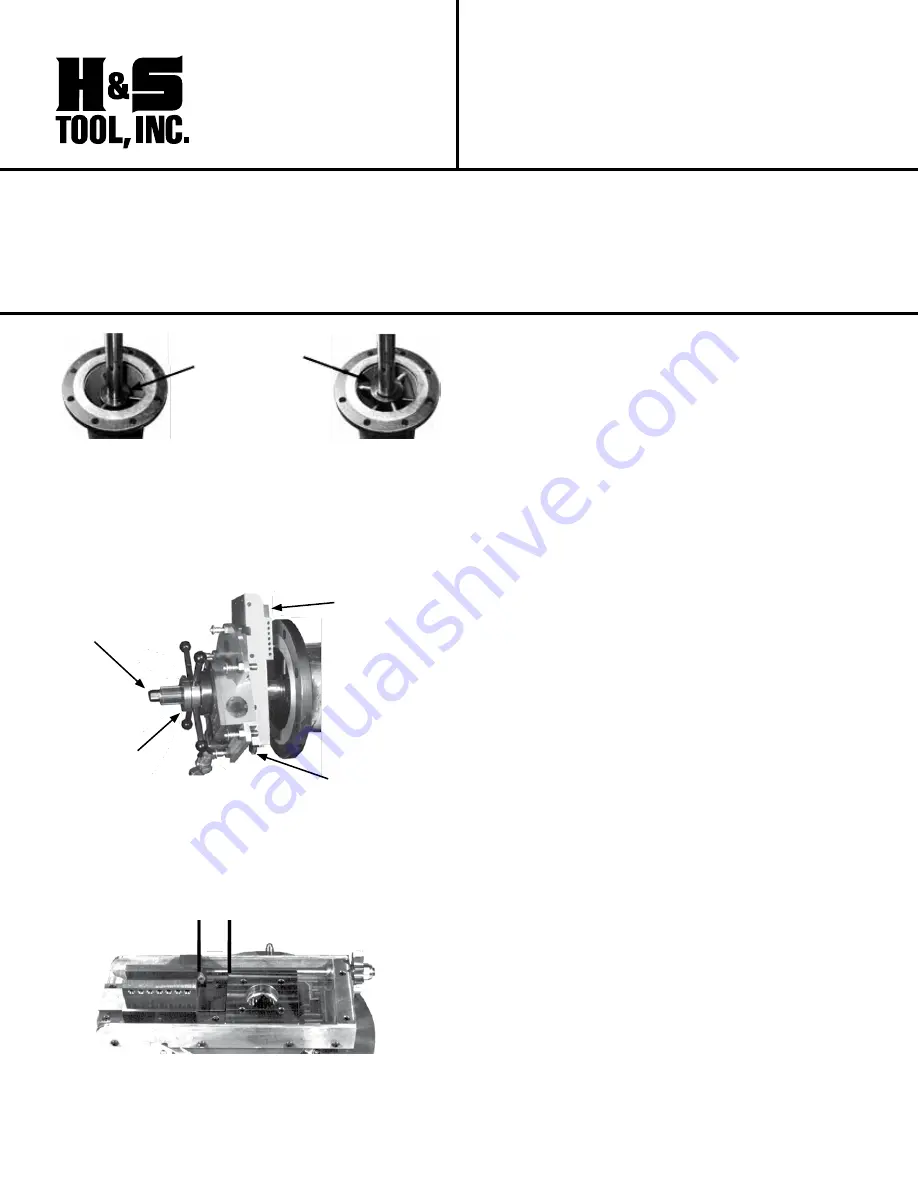

Elbow

Mandrel

Mandrel

Support

Bushing

1. Install the appropriate elbow mandrel in the pipe

I.D. in accordance with the instructions provided with

the mandrel. For accuracy, the elbow mandrel is highly

recommended over the wedge sets. The mandrel

support bushing should also be installed to increase

rigidity and reduce the occurrence of chatter.

Low or High

Range Tool

Holder

Feed Nut

Cap Screw

Ratchet on

Trip Wheel

2. Mount the power unit/flange facer assembly onto the

centershaft by aligning the splines and engaging the

feed nut.

3. Install the low or high range tool holder (depending

upon the flange size) in the tool block.

A

NOTE: Make sure that the distance (A) between the

female slide block and the body is greater that the width

of the flange surface to be machined. Reposition as

necessary. All trip pins must be disengaged.

4. Assure that the area around the machine is clear.

Begin rotating the flange facer and advance the feed nut

until the insert makes contact with the surface. Stop the

machine and note the position of the handles on the

feed nut. Turn the feed nut counter clockwise 1/2 turn to

disengage the insert from the face.

5. Position the insert outside of the flange surface to be

machined by rotating the trip wheel with the ratchet and

socket.

6. Return the insert to the contact depth by turning the

feed nut 1/2 turn clockwise. See specifications below for

approximate adjustment dimensions. Lock the feed nut in

position by tightening the cap screw.

7. Clear the backlash by rotating the trip wheel clockwise

when looking at the nut by hand. Once you feel

resistance, position the next tip of the star wheel so it

points directly at the trip ring (model MFT) or bracket

(model MT). Failure to perform this procedure will result

in damage to the trip pins.

8. Proper adjustment of the gib is necessary for an even

cut and proper timing. The gib is properly adjusted when

there is resistance to turning the trip wheel by hand.

Adjustments are made by turning the gib screw

clockwise to loosen.

9. Engage the desired number of trip pins for the surface

finish required (See specifications below).

10. Allow the machine to run until the flange has been

completely resurfaced.

Specifications

Working

Range: 4.25" I.D. (108.0 mm) to 16.25" (610.0 mm) O.D.

Radial Tool Clearance: 11.0" (279.0 mm)

Radial Feed Rate - .005" (0.13 mm) per pin: All 6 pins .030"

(0.76 mm) Per Revolution Note: Pins must be engaged at

opposing positions for even resurfacing.

Approximate surface finishes are:

1 pin — 63 RMS 3 pins — 125 RMS 6 pins — 500

RMS

Axial Feed Rate: .083" (1.6 mm) Per Full Feed Nut Turn

Approximate Feed Depth Adjustments are:

1/4 turn — .021" (0.38 mm) 1/2 turn — .042" (0.79 mm)

3/4 turn — .063" (1.2 mm)