HAMWORTHY HEATING LTD

LILLIPUT HE

500001047/F

10

ensure they remain in position.

e.

Remove the two reducing plugs - located at

the top and bottom of the front section.

f.

Fit the boiler assembly tools* - one through

the flow (top) connection and the other

through the return (bottom) connection and

evenly compress the sections together.

g.

Fit the four tie rods, tighten the tie rod nuts to

a torque of 35 Nm (26 lbf.ft), and then

carefully remove the two assembly tools.

Replace the two reducing plugs in the front

section and fit the thermostat pocket and

drain valve in the top and bottom plugs

respectively. Slide the stainless steel baffle

plate into the roof of the combustion chamber

(see item 24 Fig 4) locating the returned

edges between the section fins.

h.

Fit the front door and rear combustion

chamber plate, together with ceramic

insulation, and secure with the nuts provided.

N.B.

The front boiler door may be hinged on either

left or right side, as required.

i.

Fit flue box to rear section and secure using

the screws provided.

j.

On completion of assembly, the heat

exchanger should be hydraulically pressure

tested to 1.5 times the maximum system

pressure operating for 30 minutes (BS779 -

1989, Amendment 1 - 1993).

•

Boiler assembly tools are available on loan,

from Hamworthy Heating Ltd.

6. BOILER

ASSEMBLY

6.1 Boiler

Sections

The heat exchanger is made up from THREE or

FOUR different types of section, each weighing

around 32kg (70 lb), as follows:

•

One rear section (R)

•

One front section (F)

•

Intermediate sections (I)

•

Special intermediate sections (SI)

For the purposes of identification the 'Intermediate'

sections have a joint face between the middle and

upper part of the section, whereas the 'Special

intermediate' sections do not.

These sections MUST be assembled in the correct

sequence working from the rear of the boiler as

detailed in table 4 above.

6.2 Assembly

Procedure

If it has been necessary to dismantle the boiler for

any reason, the following procedure should be

adopted to re-assemble it:

a.

Position the rear section and thoroughly clean

the nipple seatings (at both top and bottom of

the section) and the mastic rope groove

around the perimeter of the section.

b.

Taking two new nipples, smear them with

suitable nipple sealant and insert them into

their seatings - ensuring that they are at right

angles to the face of the section. Fit new

mastic rope into the groove around the

section.

Should the mastic rope break during this operation

the two ends must be overlapped and pressed

together to avoid the possibility of leakage.

c.

Taking an intermediate section, thoroughly

clean the four nipple seatings and the mastic

rope grooves, and then carefully fit it to the

rear section - locating the two nipples into

their corresponding seatings.

d.

Repeat this operation for each of the

remaining intermediate, special intermediate,

and front section, using new nipples and

mastic rope at each joint. The intermediate

sections may need support on chocks to

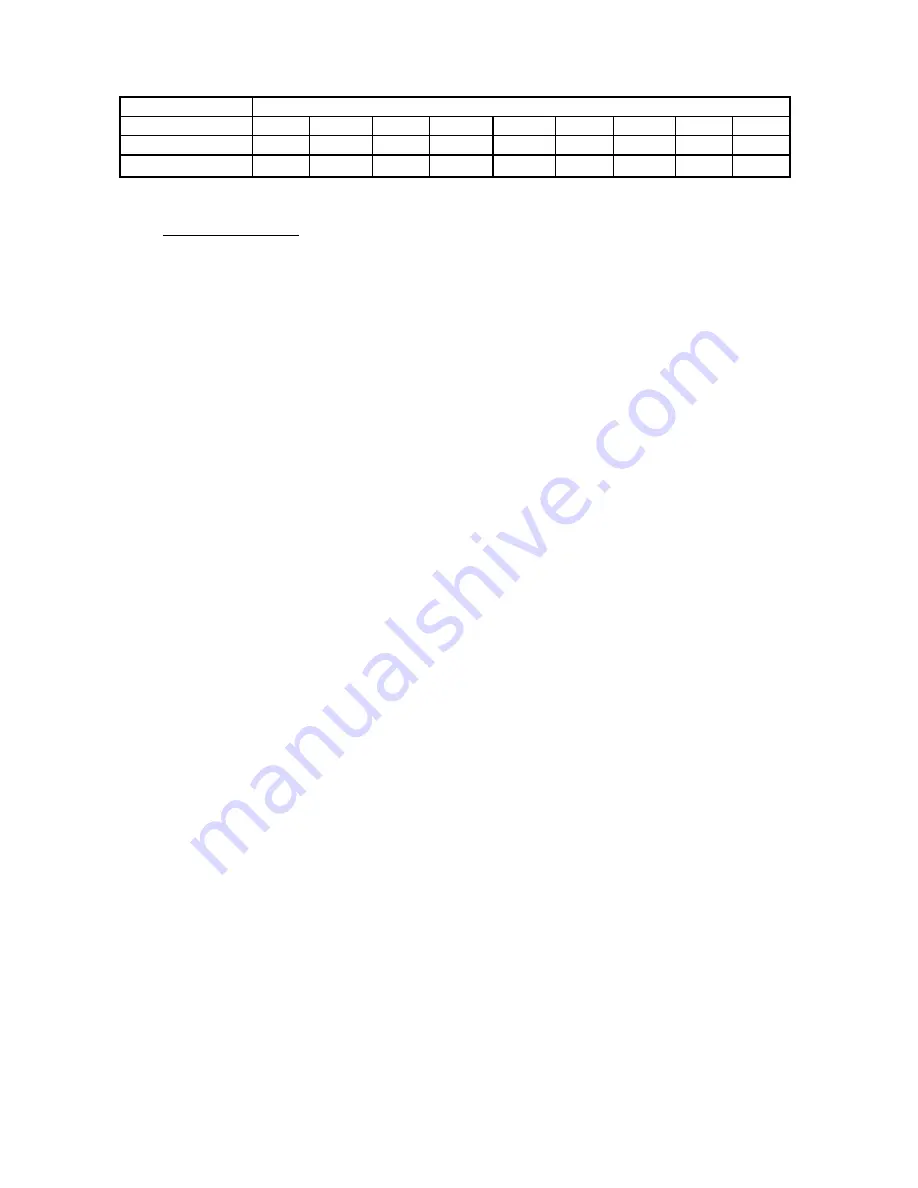

BOILER

SECTION TYPE

LILLIPUT HE 65

R

I

I

I

I

SI

F

LILLIPUT HE 90

R

I

I

I

I

SI

SI

SI

F

No. FROM REAR

1

2

3

4

5

6

7

8

9

TABLE 4.Composition of Sections within Heat Exchanger