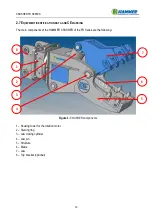

Insert the pins of the arm and the joint cover in their

respective seats and secure them with screws and nuts.

The tightening torques of the nuts depend on their size. In

this regard, see the table in § 6.6, "Tightening Torques of

Screws and Nuts".

Connect the rotation hydraulic pipes (only for the FR and FK

versions) (after verifying that the operating pressure and flow

rate exiting the excavator are those prescribed in the

technical specifications for the specific CRUSHER model),

making sure that they do not have any defects.

The dimensions of the pipes are shown in the following §

6.8, "Hydraulic pipe dimensions".

Please note: during use, the hydraulic connections must be

constantly under pressure.

Connect the hydraulic pipes related to the opening/closing of

the jaw (after verifying that the operating pressure and flow

rate exiting the excavator are those prescribed in the

technical specifications for the specific CRUSHER model),

making sure that they do not have any defects.

The dimensions of the pipes are shown in the following §

6.8, "Hydraulic pipe dimensions".

Please note: during use, the hydraulic connections must be

constantly under pressure.

Perform the entire range of the possible positions slowly, acting on the excavator control cylinder. Check for the

absence of collisions and that the connection pipes are correctly positioned (they must not be crushed or blocked).

To disassemble, carry out the steps described above in reverse order.

CAUTION

● In the event of incorrect connection of the CRUSHER and the related equipment,

serious dangers can be created for the safety of people.

● If the clamping screws of the pressurized hydraulic pipes become loose or are

loosened, they can be disconnected by lashing movements and can cause serious

injury to people.

● If quick couplings are used, always clean them before assembly or disassembly.

● Always close pipes and fittings with tight and clean end caps when disassembling the

equipment.

27

CRUSHER FR SERIES