Supplied By www.heating spares.co Tel. 0161 620 6677

25

32

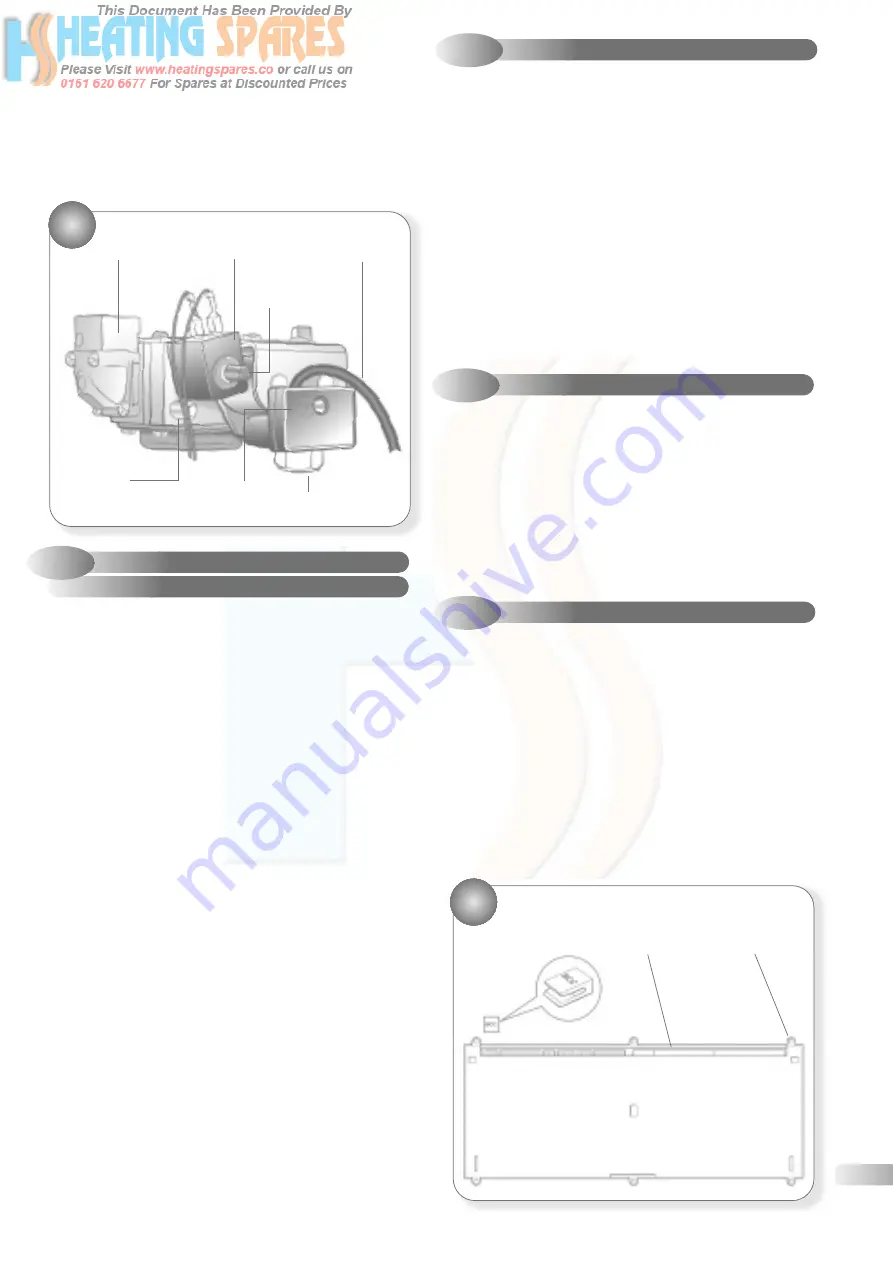

MUL

TIFUNCTIONAL GAS CONTROL

Gas outlet flange

Modureg

Electrical lead

DHW Burner

pressure adjuster

Burner pressure

test point

Inlet pressure

test point

Gas service cock

•

•

•

•

•

•

•

9.5.2

GAS CONTROL BURNER PRESSURE

SETTING PROCEDURE

Refer to Figs. 32

a)

Connect a suitable manometer to the bur

ner pressure test

point. Turn on the gas supply.

Check for gas tightness taking the precautions described in

section 5 and re-commission the appliance in accordance with

section 5.3.

Note:

It is only possible to set the DHW heat inputs because the

CH heat inputs are electronically set by the control.

A 2mm and 3mm Allen key ar

e required for this adjustment.

a)

T

urn the DHW temperature control knob fully clock-wise to the

Comfort position and fully open any DHW tap to ensure that

the boiler fires at full rate.

b)

Remove the cap fr

om the pressure adjuster and insert the Allen key.

c)

T

urn the small diameter shaft clockwise to increase, or anti-

clockwise to decrease the burner pressure. Set to 15.5 mbar

(6.2 in wg) Nat. Gas, 23.4 mbar (9.4 in wg) Propane.

d)

Disconnect one of the low voltage electrical leads fr

om the

Modureg to reduce the rate to minimum.

e)

T

urn the large diameter shaft clockwise to increase, or

anti-clockwise to decrease the burner pressure. Set to 1.0

mbar (0.4 in wg) Nat. Gas, 2.3 mbar 0.92 in wg Propane.

f)

Reconnect the Modur

eg lead and replace the adjuster cap.

g)

Close the DHW tap and ensur

e that the burner is

extinguished and the pump stops after a brief overrun

period. Remove the pressure gauge and tighten pressure

test point screw, open the DHW tap to re-light the burner

and test for gas tightness screw.

h)

Close the DHW tap, r

e-assemble in reverse order and ensure the

plastic cap is refitted and a blob of paint re-applied to seal it.

9.6

AIR PRESSURE SWITCH

Refer to Fig. 29

a)

Ensur

e supply voltage is isolated.

b)

Remove the casing fr

ont panel and sealed chamber front

panel. Refer to section 9.3.

c)

Disconnect the sensing pipes fr

om the pressure switch.

Note that the short pipe from the flue gas sampling point is

connected to the rear (-ve) connection on the pressure switch.

d)

Disconnect the electrical leads fr

om the pressure switch, noting

their positions.

e)

Remove the two securing scr

ews and withdraw the switch from

the boiler.

f)

Fit the new pr

essure switch and re-assemble in reverse order,

referring to the wiring diagrams (section 7) if necessary.

9.7

DIVERTER VALVE ACTUATOR

Refer to Fig. 33

a)

Ensur

e supply voltage is isolated.

b)

Remove the casing fr

ont panel and lower the controls fascia

panel. Refer to section 9.3.

c)

Unplug the electrical lead fr

om the actuator.

d)

W

ithdraw the retaining clip to release the actuator from the

head of the diverter valve.

e)

Fit the new actuator and r

e-assemble in reverse order.

9.8

PCB

Refer to Fig. 29 and 33

a)

Ensur

e supply voltage is isolated.

b)

Lower the contr

ols front panel and lower the control fascia

panel. Refer to section 9.3.

c)

Unplug the electrical leads fr

om the PCB. Refer to section 7.

d)

Remove the PCB plastic cover

.

e)

Unclip the PCB and withdraw

.

f)

Car

efully remove the three control knobs, noting their position

and fit onto new PCB.

g)

Fit the new PCB and r

e-assemble in reverse order. Ensuring

control knobs are free to move and reset button operates.

33

PCB HOUSING

NG/Pr

opane

chip card

Electrical

Connectors

Securing

Screws

•

•

e)

Disconnect the two electrical leads fr

om the Modureg.

f)

Ensur

e that the gas supply is turned OFF and remove the four

socket screws securing the gas service cock to the gas control.

g)

Remove the four scr

ews securing the gas outlet flange to

the gas control.

h)

W

ithdraw the gas control from the boiler.

i)

Fit the new contr

ol and re-assemble in reverse order, ensuring

that the ‘O’ rings are correctly fitted.