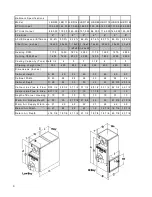

Table 10 Riello Burner Specifications

Furnace Model

Burner

Model

Nozzle Pump

Press.

Air

Setting

1

Turbulator

Setting

Tube

Length

Insertion

LB/HB85

40F3

0.65X60

º

W

160 4.50 0.5 8-7/8”

5-3/4”

LB/HB115

40F3

0.85X60

º

W

160

3.25

2.0

8-7/8”

5-3/4”

LB/HB145

40F3

1.00X60

º

W

160 3.75 3.0 8-7/8”

5-3/4”

LB/HB160

40F5

1.10X60

º

W

160

6.00

3.0

8-7/8”

5-3/4”

Notes: 1. Approximate air settings see start up procedures for final adjustments

2. Burner Amulet Required

Table 11 Carlin Burner Specifications

Furnace Model

Burner

Model

Nozzle Pump

Press.

Air

Band

1

Air Bar

1

Tube

Length

Insertion

LB/HB85

EZ-1

0.65X70

º

W

2

140 0.65 0.60-0.65 9” 5-3/4”

LB/HB115

EZ-1

0.85X70

º

B

2

140

0.85

0.85-1.00

9”

5-3/4”

LB/HB145

EZ-1

1.00X70

º

B

2

140 1.00 0.85-1.00 9” 5-3/4”

LB/HB160

EZ-1

1.10X70

º

B

2

140

1.10

1.10-1.25

9”

5-3/4”

Notes: 1. Approximate air settings - see start up section for final adjustments

2. Delavan nozzle 3. Hago nozzle

Wiring

Electric shock hazard can cause severe personal injury or death if power source,

including service switch for the furnace, is not disconnected before installing or servicing the unit.

WARNING

All wiring must conform to the National Electrical Code NFPA 70, latest edition and any additional

state or local codes.

All wiring must be N.E.C. Class 1. If original wiring as supplied with the furnace must be replaced,

replace with type 105

º

C wire or equivalent only.

Power

Supply wire for the furnace must be sized for the load requirement as listed on the furnace rating plate.

Connect 120 VAC 60HZ single phase separate electrical line from the main house panel to the power

leads in the junction box attached to the furnace as indicated in the electrical wiring diagrams.

Provide a fused disconnect in the power line following all code requirements. Connect the burner to

the factory wired burner harness as shown in the electrical diagrams.

Provide electrical ground at the furnace as required by codes.

16

Summary of Contents for HBD1 15

Page 17: ...17 17...

Page 31: ...31...