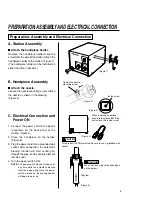

HEAT CONTROL

POWER

AIR CONTROL

1

2

3

4

8

7

6

5

1

2

3

4

8

7

6

5

Temperature control knob

Air flow control knob

OPERATION

●

●

●

●

●

QFP Desoldering

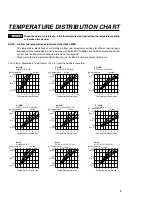

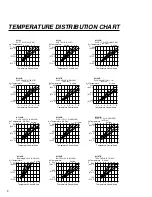

1. Adjust the air flow and temperature

control knobs.

Refer to the temperature distribution chart

(page 8) to adjust the air flow and temper-

ature control knobs. Wait for the temper-

ature to stabilize for a short period of time.

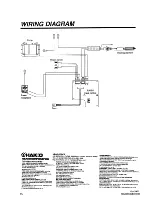

WARNING

If the thermal protector is tripped (the heater

lamp turns off during use), reduce the tem-

perature setting or increase the air flow. Be sure

not to operate the unit with temperature and air

flow settings that makes the thermal protector

trip. This could damage the unit.

2. Place the FP pick-up under the IC lead.

Slip the FP pick-up wire under the IC lead.

(Refer to the photo shown.)

If the width of the IC does not match the

size of the FP pick-up, adjust the width of

the pick-up by squeezing the wire. In case

of PLCC or small components such as

chip resistors, desolder by using

tweezers, etc.

3. Heating

Hold the handpiece so that the nozzle is

located directly over, but not touching the

IC, and allow the hot air to melt the solder.

Be careful not to touch the leads of the IC

with the nozzle.

4. Remove the IC.

Once the solder has melted, remove the

IC by lifting the FP pick-up.

5. Remove any remaining solder.

After removing the IC, remove remaining

solder with a soldering iron and wick or

desoldering tool.

5

Summary of Contents for 850B

Page 15: ......