Haklift Oy

Asessorinkatu 3-7

20780 Kaarina, Finland

Tel. +358 2 511 5511

www.haklift.com

Lifting Solutions Group

Axel Johnson International

CHAIN

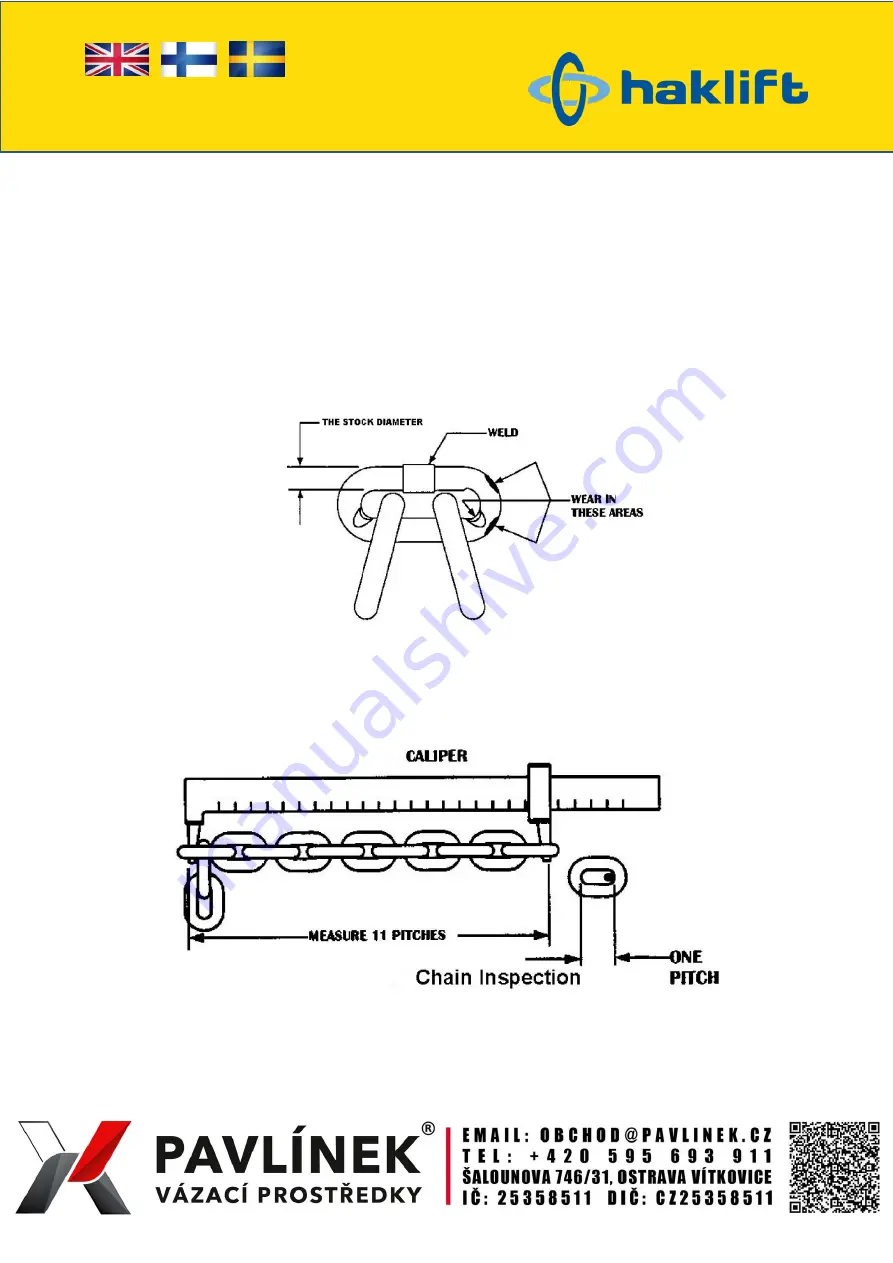

1. Clean chain with a non-caustic/non-acid type solvent and make a link by link inspection for nicks, gouges,

twisted links, weld splatter, corrosion pits, striations, cracks in weld areas, wear and stretching. Chain with

any one of these defects must be replaced.

2. Slack the portion if the chain that normally passes over the liftwheel. Examine the interlink area for the point

of maximum wear. Measure and record the stock diameter at this point of the link. Then measure stock

diameter in the same area on a link that does not pass over the liftwheel and compare these two

measurements.

3. Also check chain for stretch using a larger caliper as show below to measure the outside length of a

convenient number of links about 11 (pitchs). Measure the same number of links in a used section of chain

and calculate the percentage increase in length of the worn chain.

4. Chain is to be kept clean and lubricated. Visually check chain every time chain hoist is used. As oil needs

to sit at the bearing surface of each chain link, it is advised to submerge the chain in oil for 30 min. Take it

out and let the chain hang dripping for 24 hours before putting in the hoist.