25

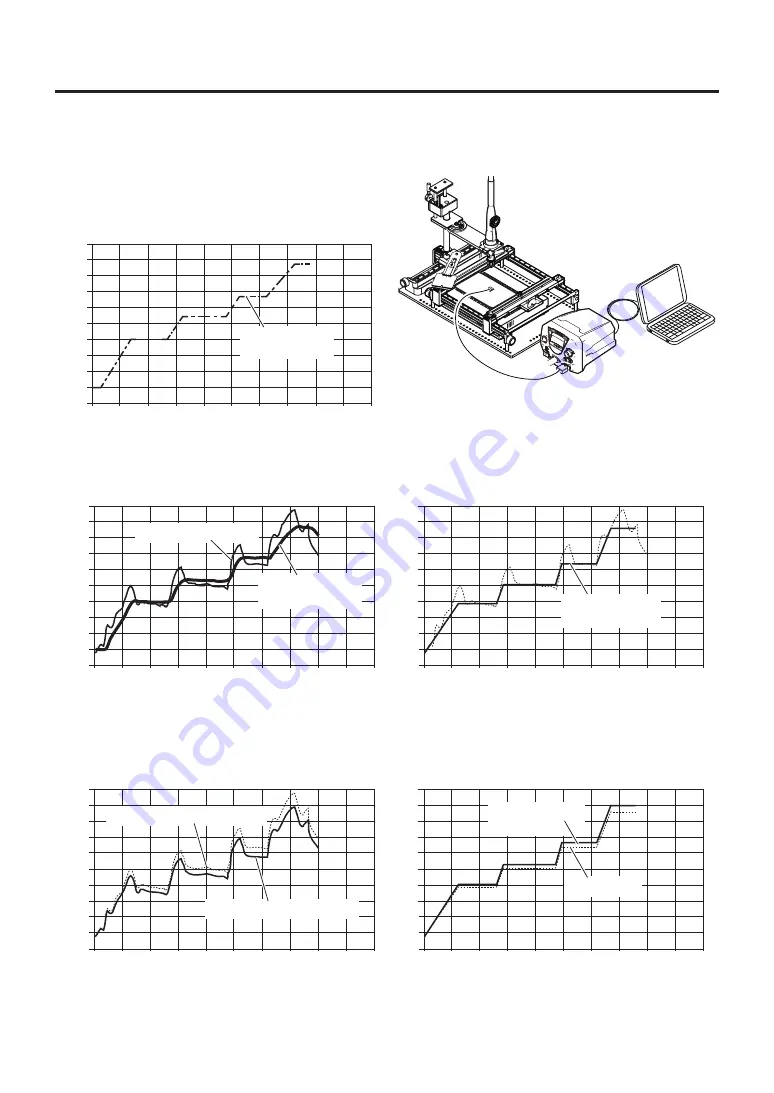

※Example of using C.O.F. (Change on the fly)

1. Select "PART" in "Sensor selection" (refer to page 11), and attach the thermocouple to the part.

2. Look up the temperature conditions for removing

the part and perform profile settings.

3. When removal is performed according to the settings, the temperature graphs for both the part and

the soldering iron heater will be shown as shown at left below. Select "TOP" in "Sensor selection" and

set the profile from the heater temperature graph.

0

0

30

60

90

120

150

180

210

240

270

300

30

90

120

150

180

210

240

270

300

60

[

℃

]

[sec]

0

0

30

60

90

120

150

180

210

240

270

300

30

90

120

150

180

210

240

270

300

60

[

℃

]

[sec]

0

0

30

60

90

120

150

180

210

240

270

300

30

90

120

150

180

210

240

270

300

60

[

℃

]

[sec]

Part temperature

graph

Heater temperature graph

Part temperature

profile (setting)

Profile (setting)

based on graph

0

0

30

60

90

120

150

180

210

240

270

300

30

90

120

150

180

210

240

270

300

60

[

℃

]

[sec]

Initial setting

4. Prepare a different board and remove the same part using the profile set in step 3. If the actual

measured value is different than the expected temperature, use "C.O.F." to change the set temperature

for each ZONE. (please refer to page 14 for changing settings.)

5. The changed profile can be used to remove parts from boards under the same conditions from then on.

0

0

30

60

90

120

150

180

210

240

270

300

30

90

120

150

180

210

240

270

300

60

[

℃

]

[sec]

Setting changed

using C.O.F.

Expected temperature graph

Actual temperature graph

Summary of Contents for FR-811

Page 47: ...46 MEMO...