507961-01G / 31-5000653

Page 37 of 57

Issue 2128

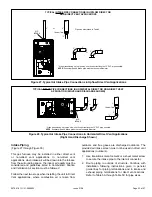

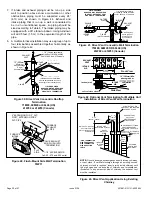

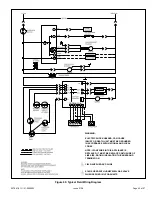

Figure 57.

When testing pressure of gas lines, gas valve must be

disconnected and isolated. See Figure 57. Gas valves

can be damaged if subjected to pressures greater than

1/2 psig (3.48 kPa).

IMPORTANT

NOTE - BLACK IRON PIPE

ONLY

TO BE ROUTED INSIDE OF CABINET

FIELD

PROVIDED

AND INSTALLED

GROUND

JOINT

UNION

DRIP LEG

MANUAL

MAIN SHUT-OFF

VALVE

Upflow Application

Right Side Piping

(Alternate)

Gas Valve

In LP/Propane applications, a 4” BIP nipple must be

installed to allow clearance for the low inlet pressure switch.

GROUND

JOINT

UNION

Upflow Application

Left Side Piping

(Standard)

DRIP LEG

MANUAL

MAIN SHUT-OFF

VALVE

AUTOMATIC

GAS VALVE

(with manual

shut-off valve)

Gas Valve

Figure 58.

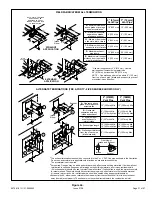

Upflow Applications

Possible Gas Piping Configurations

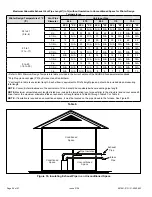

Figure 59. Horizontal Applications

Possible Gas Piping Configurations

NOTE - BLACK IRON PIPE

ONLY

TO BE ROUTED INSIDE OF CABINET

FIELD

PROVIDED

AND INSTALLED

GROUND

JOINT

UNION

DRIP LEG

MANUAL

MAIN SHUT-OFF

VALVE

Horizontal Application

Right-Side Air Discharge

Gas Valve

GROUND

JOINT

UNION

DRIP LEG

MANUAL

MAIN SHUT-OFF

VALVE

GROUND

JOINT

UNION

DRIP LEG

MANUAL

MAIN SHUT-OFF

VALVE

Horizontal Application

Left-Side Air Discharge

Gas Valve

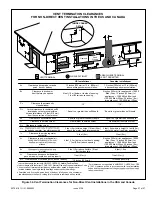

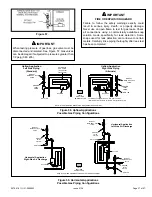

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could

result in serious injury, death, or property damage.

Never use an open flame to test for gas leaks. Check

all connections using a commercially available soap

solution made specifically for leak detection. Some

soaps used for leak detection are corrosive to certain

metals. Carefully rinse piping thoroughly after leak test

has been completed.

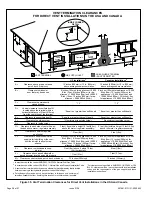

IMPORTANT